Prepare for a lot of new information – topRik’s team goes in depth on water quality control and testing onboard your yacht with watermaker installed. We will not explain the basics of watermaker’s internal design or its installation (you can find other articles on these topics on the website). Here we cover: importance of various factors like salinity and pH levels, different testing methods and usage of kits, monitoring and data analysis, test interpretations and arising problems. Buckle in!

Water Quality Standards

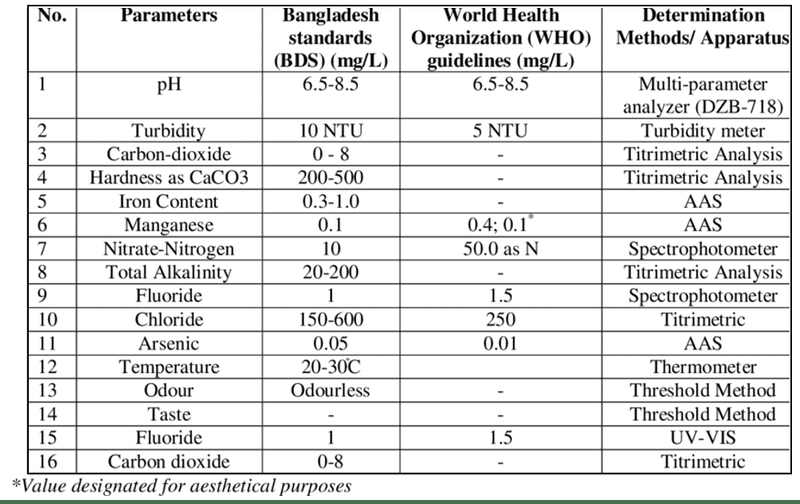

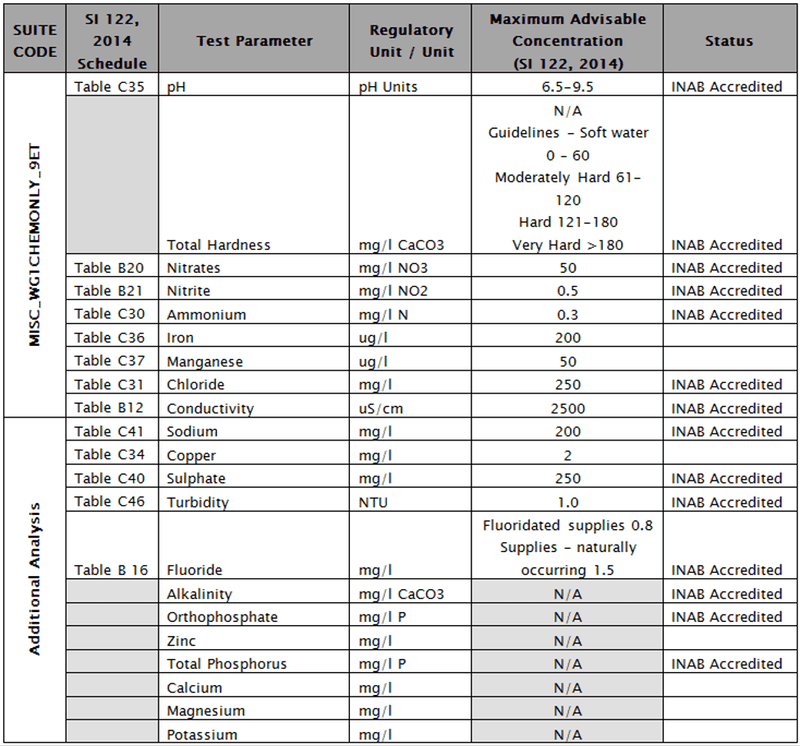

National and international guides and regulations serve as guiding stars to ensure the purity and safety of the freshwater produced by any marine water maker. For example, while in the United States the Environmental Protection Agency (EPA) describes water quality standards in its Water Quality Standards Handbook, there are also internationally recognized standards that yacht owners and operators should consider.

World Health Organization (WHO) Guidelines

The WHO provides excellent guidelines for drinking water quality with a comprehensive framework for calculating and managing risks associated with all kinds of contaminants – they include microbiological safety, chemical pollutants and aesthetic aspects of water quality, resulting in a globally recognized benchmark for yachtsmen around the world when it comes to marine watermakers.

| *Parameter | FEPA Standards | WHO Standards |

|---|---|---|

| pH | 6-9 | 6.5-9.2 |

| Total Hardness | - | 300 |

| Total Dissolved Solid | 2000 | 500 |

| Electrical conductivity | - | 300 |

| Total Coliform Count (100ml) | 0 | 0 |

| Sulphate | 20 | 200 |

| Sodium | - | 200 |

| Ammonium | 0.01 | 1.5 |

| Zinc | 5.0 | 5.0 |

| lron | 0.05 | 0.3 |

| Lead | 0.01 | 0.05 |

| Cadmium | 0.05 | 0.01 |

All values in mg/L, except pH, EC (uS/cm) and Total coliform count (CFU/ml): FEPA (1991), WHO (1997), WHO (2003).

International Maritime Organization (IMO)

The IMO is the child of the United Nations, which is responsible for the safety, security and environmental performance of international shipping. It actually does not have specific water quality standards for yacht watermakers, but its guidelines and regulations regarding contamination prevention and control in marine environments still greatly affect the practices of the yachting community.

International Organization for Standardization (ISO)

ISO develops and publishes international standards across various industries, including water quality. More specifically, ISO 24510:2007 and ISO 16075-1:2015 are directly related to watermakers and provide helpful guidance when it comes to the usage and maintenance of desalination devices. Basically, best advices on performance, efficiency and safety considerations set in stone for everyone.

National Regulations and Standards

Yachtsmen should also consider the water quality standards and regulations that are specific to certain countries. These may include requirements related to water treatment, quality testing, allowed levels of contaminants. The European Union, for example, has established the Drinking Water Directive (98/83/EC), which sets standards for drinking water quality within all its member states.

Following these international standards helps you to meet a certain criterion for drinking water quality and safety. Even though it might sound like too much work, you better stay updated on the latest international standards and local regulations to provide the highest quality water for yourself and passengers onboard your yacht.

Water Quality Factors

Now that we discussed staples of water quality control, we have to first figure out what is it that makes the water just right. Here are main factors to consider.

Salinity

High levels of salinity in the source water always pose a challenge, especially for cheaper systems, requiring additional energy and resources to get rid of the pesky salts – you must always monitor the water before it goes inside the device to achieve optimal performance. And when it comes to water that was already processed, monitoring salinity levels is an essential endeavor to ensure that the watermaker does its thing.

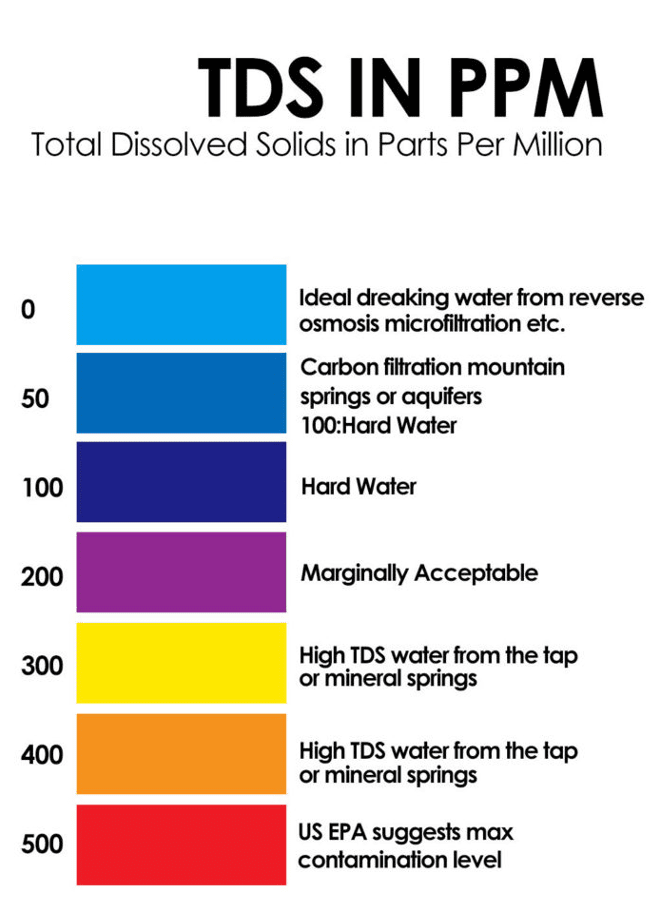

Total Dissolved Solids (TDS)

These three letters represent a vast array of salts, minerals and organic compounds that shape the final composition of the water. The level of TDS in source water directly influences the taste and quality of the freshwater produced by marine water makers. A delicate balance is needed here, as elevated levels can will make the water too impure to use and potentially can even cause harm to the water maker itself. Constant monitoring and control of TDS levels is a good habit to have for skippers and crewmen.

pH Levels

The dance between acidity and alkalinity is a topic on which many, many scientific papers are written. In short, marine water makers thrive within specific pH ranges, as any deviation can trigger a cascade of unwanted consequences, like corrosion nibbles at the edges or water that is impossible to drink or use. We talk more about the methods of testing pH levels below.

| Substance | pH Level |

|---|---|

| Stomach Acid | 1.5 - 3.5 |

| Lemon Juice | 2 - 3 |

| Vinegar | 2.5 - 3.5 |

| Tomato Juice | 4 - 4.5 |

| Black Coffee | 5 - 5.5 |

| Normal Rainwater | 5.6 |

| Urine | 6 - 7 |

| Distilled Water | 7 |

| Saliva | 6.2 - 7.4 |

| Blood | 7.35 - 7.45 |

| Seawater | 7.5 - 8.4 |

| Milk | 6.5 - 6.7 |

| Hand Soap | 9 - 10 |

| Ammonia | 11 - 12 |

| Sodium Hydroxide (Lye) | 13 |

| Bleach | 12.5 - 13.5 |

Bacterial Contamination

This kind of contamination is an example of life getting in the way – there are tons of microorganisms that are living in whatever you drink. We are fine with some of them and want others to be gone. Pathogens like bacteria, viruses and protozoa can unleash waterborne illnesses on the whole group of passengers and crew, who consumed the resulting water. By understanding the sources of contamination and implementing robust disinfection procedures, you might save someone from getting Legionnaire’s disease and vibriosis, going through fever, abdominal pains and other “fun” experiences.

Water Testing Methods

To unlock the secrets within the drop of water, an arsenal of testing methods and tools is at our disposal. These methods serve as a bridge between the invisible subtleties of water quality and a full glass. Let us explore two key avenues in the realm of water testing.

Testing Kits and Equipment

Good testing kits and equipment are robust and portable, include a whole array of tools, from test strips to colorimetric reagents, enabling boaters to perform basic water tests with ease without a need for a personal lab. With them you can measure salinity, TDS levels, and pH values. Read the manual on the purchased kit carefully and, if possible, find a video tutorial – even though such kits might have similarities, it would not be appropriate to give general advice when it comes to using it, since what’s right for one kit could be wrong for another.

Laboratory Testing Services

Professional laboratory testing services offer a comprehensive analysis of water quality parameters, providing an extensive range of tests and examinations – and not for free. Armed with cutting-edge equipment and techniques, these laboratories unravel the mysteries of water quality with meticulous precision – and go for your wallet in the process. But that’s how it is – if you want to conduct the most precise tests to get a certain staple when it comes to your equipment, it is still worth the price. You will not have to do it all the time after you establish the main principles for you particular watermaker.

From bacterial contamination to the presence of specific contaminants, laboratory testing will show it all. It is very useful if you are sailing only within a certain area – you can send the samples to the lab, optimize your watermaker using the results and enjoy high-quality water until the next life-changing natural or man-made disaster.

No matter how expensive the testing kit is, the lab results will always be more precise, allowing you to fine-tune your device perfectly. The problem is, it is not flexible – testing takes time, cannot be done along the voyage, and, to some people, it destroys the joy of exploration and danger that comes with doing it all by yourself without relying on science too much. Also, you will not be able to engage into regular testing unless you dedicate a whole saloon to your own lab onboard. It’s up to you to decide which route to choose – maximum independence or maximum precision.

Regular Testing and Monitoring

Without these two activities it will not be easy to even justify the purchase of the watermaker in the first place. These essential practices ensure the early detection of potential issues and pave the way for proactive measures.

Frequency of Testing

Just like ebb and flow of the sea, the frequency of water testing procedures better follow a consistent pattern. Factors such as water usage, environmental conditions, and regulatory requirements dictate the appropriate intervals between tests of both source and freshwater. By establishing a well-defined testing schedule, crewmen and owners can ensure that the quality of both source and processed water remains within acceptable limits. Whether it be daily, weekly, or monthly, it is the consistency that matters. For source water you can use one of these, they are called handheld meters.

Record Keeping and Data Analysis

The diligent recording of test results forms a certain historical record of water quality parameters, convenient to address later, since you are not going to remember it all. It is also very useful in case of the charters, where the skippers change but watermakers don’t. By meticulously maintaining these records, various trends and patterns can be identified, enabling you to predict problems in the future and adjust the device accordingly.

Interpreting Test Results

It is not enough to get good data, you also need to read and understand it right, otherwise the best testing kit will be another waste of money.

Understanding Test Results

The readings might seem like gibberish at first, especially if you skipped chemistry at school.

But there’s a reason we mentioned international standards in the beginning – after you read the manual, follow the procedure and determine, let’s say, pH level, you should compare it to acceptable levels according to WHO or IMO. Do this with every single water parameter and you are set. The manual of your specific testing kit is your best friend here too – something like the correct usage of acidifying GP-tablet to determine chlorine high range is not always easy to figure out on your own.

Addressing Issues and Making Adjustments

Test results often reveal deviations from desired parameters, but the negative result is still result. By identifying these issues promptly, yachtsmen can take decisive action to address them: adjusting system settings, implementing additional treatment methods or exploring alternative water sources. Making adjustments based on test results allows for the continued production of clean and safe freshwater.

Common Water Quality Issues

The resilience and problem-solving skills of a skipper will definitely get tested from time to time by some shady water sources and inexplicable taste or smell of resulting water. Luckily, all good water makers (including those for sale at our marketplace) are made with constant adjustments in mind. Here are some of the problems, leading to low quality of source water, resulting in high TDS levels and contamination.

Causes and Solutions for High Salinity

High salinity levels can arise from seawater intrusion or operational inefficiencies within the desalination process. For handymen this issue will be resolved by opening the manual, checking the pumps, tubes, filter and replacing the damaged parts. For less knowledgeable, hiring a technician will do. When it comes to reverse osmosis, a method commonly used in best models, no matter how salty source water is, the molecules of salt are just not big enough to get through a membrane with microscopic holes. If a watermaker like this still produces salty water, check the membranes for damage first.

Causes and Solutions for High Total Dissolved Solids

The presence of excessive minerals, salts, or organic compounds can be addressed through additional l filtration or ion exchange. If your TDS levels are unusually high, check if you model allows to install additional filtering equipment or filters specifically meant to be used with such a difficult source. Yes, it is going to cost more, but some water sources are just more demanding. It is also likely, that the watermaker in this case will require maintenance more often after heavy usage.

Causes and Solutions for High Bacterial Contamination

The invisible threat of bacterial contamination can be resolved through rigorous disinfection procedures, regular system maintenance and choosing appropriate disinfectants. Any waterbody out there is a soup filled with microorganisms and, based on the results of your tests, you can come up with a way to get rid of unwanted guests. It is particularly important to flush your membranes with disinfectants too, as this is their main stop inside the system.

All of this might seem really complicated at first. And the case is, it actually is complicated! But don’t worry, you don’t have to be a professional chemist to tackle water control and testing issues – learn how to use your testing kit, read the manual on your watermaker, ask for an advice for a seasoned professional and you will be fine. We are always here to help with such advices in case you are looking for a watermaker of any related equipment – send us a message with your question through feedback form an we’ll try to answer ASAP. You can also use the phone number above to reach out.