This time experienced yachtsmen of the topRik marketplace explain how to ensure the smooth operation of a yacht water maker, talk about the features of its maintenance, give advice on how to troubleshoot various problems and how to properly prepare desalination equipment for a long-term or short-term downtime.

Introduction

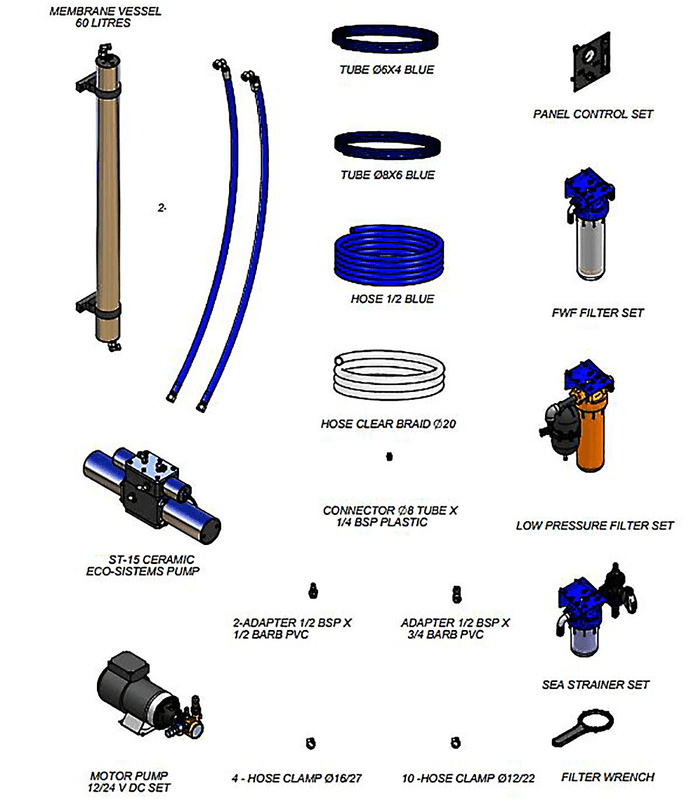

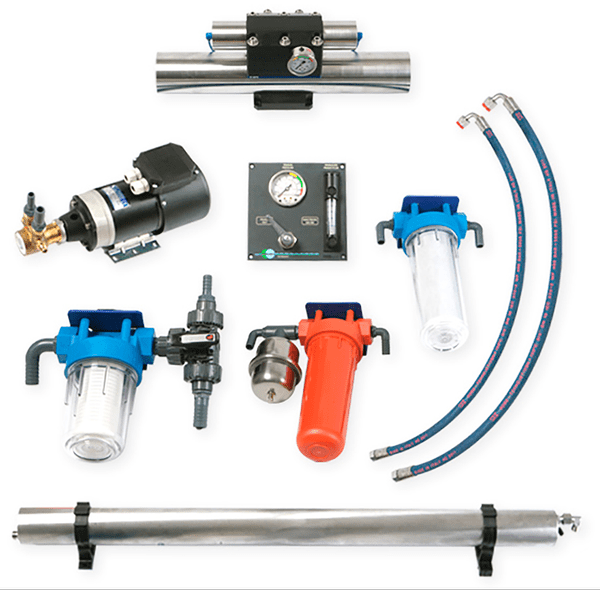

The operation of the most popular sea water makers for yachts is based on the principle of reverse osmosis. This equipment consists of many components that require routine inspection and, if necessary, replacement or repair: low and high pressure pumps, filters of various levels of purification, a set of membranes, fittings, piping systems, adapters, electric drives, etc.

Therefore, to maintain the desalination equipment in proper condition, a crew member or the boat’s owner himself (the skipper) must have the appropriate knowledge and skills. The best option is to get this knowledge from a manufacturer’s representative during the installation of the desalination equipment, comparing its actions with the instruction manual so that you can repeat it if necessary. When buying marine water maker at the topRik marketplace, you will receive comprehensive advice from our experts on all issues related to these devices.

Importance of Proper Maintenance for Marine Water Makers

Timely and competent maintenance of a yacht watermaker is a guarantee of maintaining the proper comfort of life on board, as well as the health of passengers and crew. With long passages, the failure of desalination equipment can even become a matter of life and death for the inhabitants of the ship.

An uninterrupted supply of clean fresh water depends on a few maintenance requirements for a marine watermaker.

Violation of the requirements for the maintenance of the device can lead to membrane fouling, which gradually leads to complete failure of the equipment. The lack of preventive inspections and timely replacement of filters, pumps and seals will lead to a decrease in the quality of desalinated water and the productivity of the desalination plant, that is, to a lack of fresh water for the needs of passengers.

Overview of Basic Maintenance Requirements

These are the main activities you’ll be engaged in when maintaining the desalinator on board your yacht:

- control of the operation of desalination equipment by checking the productivity indicators of the watermaker;

- preventive inspection of all types of filters, connecting elements, valves, pumps, etc.;

- timely replacement of failed parts;

- regular flushing of membranes;

- preservation of the watermaker during its downtime.

Pre-Use Checks

The ship's water maker should be checked before going to sea after its initial installation on a yacht, after the expiration of the conservation period, as well as after the completion of repairs. After a visual inspection of the equipment, it is necessary to test its operation on the high seas.

Attention! Do not attempt to conduct testing in a marina or port where the sea water is heavily polluted with waste, oil and chemicals.

Inspection of System Components

In all three cases, when a preliminary check of the operation of the distiller is required, the components of the system are first inspected for their integrity.

Equally important is the correct arrangement of elements. The inlet valve must be below the waterline, the component parts of the modular watermaker should not be far apart from each other.

If this is not the primary installation, the condition of the filters is checked for clogging, the membranes are checked for sufficient moisture.

To prevent water or oil leaks, all connecting elements are checked: fittings, rings, nuts and bolts, brackets.

The accuracy of the measuring equipment is checked, including the salinity sensor. The oil level in the crankcase of the high-pressure pump must be checked too.

Testing the System's Performance

Once the visual inspection of the watermaker has been completed, offshore performance testing of the system is performed.

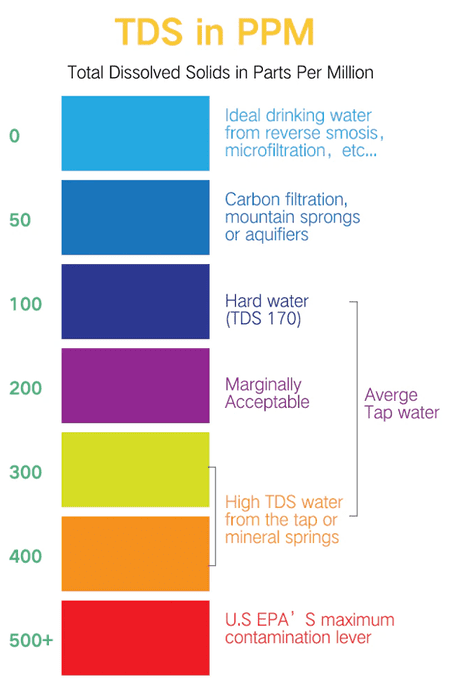

We had tested our share of such devices, so we know that the pressure in the system during testing should be increased gradually, starting from the low pressure setting for about 10-15 minutes. During this time, you will have time to inspect the system for leaks and other deviations. After you make sure that they are absent, gradually increase the pressure. When, according to the indicators, you are convinced that the declared productivity of desalinated water has been achieved, check its characteristics, including salinity, using a TDS meter.

Routine Maintenance Tasks

The main purpose of watermaker maintenance is to keep it in working condition. To do this, it is necessary to regularly flush the system with clean fresh water, monitor the condition of the primary filters, replace them in time, as well as the filters for the final purification of sea water.

Flushing the System

The principle of reverse osmosis, which is used in marine desalination plants, is to force salt water through a semi-permeable membrane using a high-pressure pump. About 10% of this flow in the form of pure fresh water molecules overcomes this obstacle and enters the yacht's fresh water tank. The remaining brine, along with contaminants and micro-organisms, is washed away by the excess feed water and pumped overboard.

At the same time, salts, bacteria and microbes dissolved in water can linger on the membrane itself from the water supply side. This leads to clogging and overgrowth of microscopic holes in the membrane. Therefore, to prevent these negative processes, regular flushing of the system with clean fresh water is required (the rinse water must not contain chlorine). Therefore, it is actually optimal to use the water produced by the watermaker itself for this purpose.

Out of offered watermakers for sale try to choose those that come with a manual or automatic membrane flushing system or consider the possibility of installing one.

If the yacht's desalination equipment had a break in operation from 3 to 6 months (depending on the region of the vessel's stay, as microorganisms spread faster in the tropics), flushing the system with a biocide is required.

Cleaning the Pre-Filtration System

The first segment of the filtration system is designed to remove contaminants larger than the molecules of dissolved salts and microorganisms. Therefore, the pre-filters become clogged much faster and are therefore installed in the desalination system immediately after the seawater supply valve.

Most coarse cleaning systems use two filters connected in series: the first is 20-30 microns, the second is 5 microns. Often this system includes an oil separator filter.

A 50 micron strainer can be installed at the inlet.

All of these filters must be cleaned regularly, both in accordance with the maintenance schedule and outside of it, if there is a decrease in system pressure and desalinator performance.

Replacing Pre-filters and Post-treatment Filters

If cleaning the filters does not restore the operating pressure and productivity of the watermaker, the pre-filters need to be replaced. And if the mineralization indicators are below the norm, the post-treatment filters are also replaced.

Scheduled Maintenance Tasks

The most important goal of water maker maintenance is achieving uninterrupted production of fresh water. If the equipment is used properly, with technicians following a preventive inspection and maintenance schedule, the guaranteed life of this equipment can be extended without major repairs. Therefore, the planned maintenance tasks include identifying the failure of individual parts and their timely replacement with spares.

Replacing the Reverse Osmosis Membrane

The service life of the reverse osmosis membrane in water desalting devices from the leaders in the production of marine equipment is around 5 years. This period can be extended if the membrane maintenance is done by the book.

If flushing the membranes with water or chemicals did not lead to normalization of the pressure and productivity of the desalination plant, while other malfunctions are excluded, the membrane must be replaced. Replacement is made if the performance decreases by 15%, and the pressure - by 10%.

Inspecting and Replacing the High-Pressure Pump

Maintenance of this most important part of the watermaker consists of changing the oil, preventing cavitation, monitoring the condition of valves and seals. The principle of troubleshooting the high-pressure pump is described in the operating instructions.

If the replacement of oil, valves and seals did not lead to the desired result, a replacement of the high pressure pump is required.

Troubleshooting Tips

We repeat once again that all possible malfunctions and the reasons for their occurrence are, as a rule, described in the operating instructions for each specific watermaker. But the main problems are common to all models of such equipment.

Common Issues and Their Solutions

The most common problems with watermakers can be eliminated on the spot:

- interruptions in the supply of sea water or lack of water supply to the watermaker - check the correct operation of the valve at the inlet, make sure that it is in the open position;

- pressure and performance in the system decreases - make sure there are no leaks in the hoses, check the condition of the clamps, fittings, seals and other connecting elements; check the condition of the low-pressure pump at the inlet and the high pressure pump, including tightness;

- the declared water quality is declining - check the condition of the filters of all levels, if necessary, clean or replace them;

- water quality and performance decrease after changing filters and membranes - check the fresh water flush line for blockages and the condition of the brine drain valve and hose.

When to Seek Professional Help

If, after all self-care measures, the desalination system is unable to achieve rated capacity, it is necessary to call a marine watermaker service specialist, who will conduct additional testing of the equipment.

Storage and Winterization

Like the yacht as a whole, some types of equipment also require special preparation for long-term or short-term storage, including in different climatic conditions. Marine watermakers are no exception.

Storage of the Marine Water Maker for Extended Periods

If your yacht is equipped with a water maker, then during breaks in sailing for a period of a week or more, and in a tropical climate - from three days, special processing of the equipment is necessary. Otherwise, salts settle on the membranes and microorganisms multiply, which renders the system useless eventually.

The membrane must first be thoroughly rinsed with clean fresh water, as after daily use, and then treated with a biomicide solution or propylene glycol, prepared according to the instructions. The next time you turn on the desalinator, do not forget to discard the produced water for the first twenty minutes of its operation until the biomicide is completely removed from the membranes.

Winterization Tips for Cold Weather Climates

If the yacht will be winterized for cold climate, and hence the watermaker, it is necessary to add a treatment with a non-toxic antifreeze solution, recommended by the manufacturer, to the process of washing with fresh water and a biomicide solution.

Safety Considerations

Like any equipment that is powered by electricity and produces wastewater containing chemicals, the maintenance of a watermaker requires compliance with safety and sanitary control rules.

Working with Electricity and High-Pressure Water

The watermaker must be connected to the power supply by a professional electrician, and operation requires compliance with the general rules for those who service electrical equipment.

It is enough to visually control the elements that water goes through under high pressure, as well as the indicators of the sensors, to prevent the troubles associated with their failure.

Proper Disposal of Waste Water and Chemicals

Disposal of brine from seawater desalination and membrane flushing with biomicide or propylene glycol must comply with wastewater and chemical disposal regulations. Solutions obtained in the process of desalination and maintenance of equipment do not pose danger to the state of water bodies and their inhabitants, therefore they can be discharged into the sea.