How to troubleshoot the desalination system on a yacht – coming from the yachtsmen of the topRik marketplace and SimpleSail. Based on their own experience, our crew try to explain why the marine water is not the most complex piece of equipment and that any skipper, who is constantly dealing with more complex yacht systems, can master it with due diligence.

Introduction

Sure, it is impossible to have a specialist on board for individual type of yacht equipment. Therefore, at best, there is a person in the crew who performs the functions of a mechanic, electrician, electronics serviceman, etc. Often this person is the skipper himself.

Therefore, experienced yachtsmen must be aware of the importance of troubleshooting for marine water maker, in case it fails in the middle of the ocean. Fresh water in sufficient quantity is vital during long journeys – the lack of it due to the breakdown of the desalination system can lead to tragic consequences, and to avoid them, you should be able to identify and fix problems in time.

The best way to prevent such a situation is to draw up a schedule of preventive examinations and strictly follow it, monitor the indicators of the sensors daily, and prevent the membranes from drying out by washing them after each use of the watermaker.

But we cannot rule out unforeseen circumstances that may adversely affect the operation of the desalination system. Well, let's not forget that one of the most devastating contingencies is the human factor. So, if there are people on board, contingencies are pretty much guaranteed, which means you should always be prepared.

The most common problems you may encounter at sea when using marine water maker:

- decrease in productivity - desalination equipment produces an insufficient amount of desalinated water or does not produce it at all;

- deterioration of water quality - increased salinity, unpleasant odor, etc.;

- leaks in the desalination system that result in both reduced productivity and poor water quality;

- unusual noises and vibrations caused by malfunctions;

- excess power consumption, generator shutdown at startup and other power supply problems.

ATTENTION! We remind you that when repairing any electrical equipment, as well as equipment operating under high pressure, you should follow the safety rules and guidelines – water and electricity are a dangerous mix.

Next, let’s get to the overview of common issues and troubleshooting procedures brought to you by our active crew.

No Water Production

There might be several reasons why a distiller cannot produce purified seawater. Below is a list of the most common ones and how to fix them.

- Insufficient water pressure – if the production of fresh water is stopped and the pressure gauges show a decrease in pressure in the system, it means the low-pressure switch was activated. The reason for the low pressure of the water flow may be leaks - all hoses and connections, as well as the feed pump bell, must be checked for integrity. Replace damaged hoses, sealing elements, fittings and other parts.

- Clogged or damaged pre-filters. The pressure in the system decreases and the relay causes the system to stop if the pre-filters are overfilled or damaged. After inspection, clean the carbon and 5-micron filters or replace the failed ones. At the same time, check the condition of the valve at the seawater inlet, set it to the required flow rate or clean it from algae if it is contaminated.

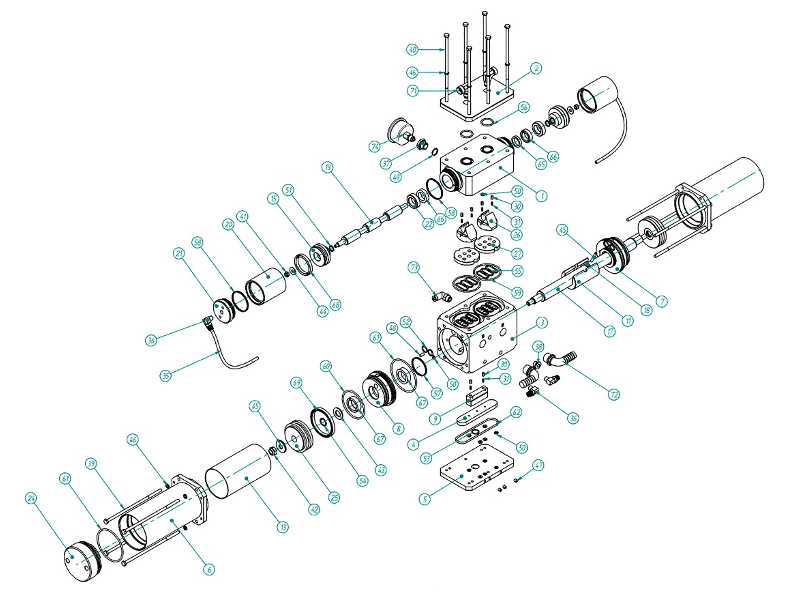

- Malfunctioning high-pressure pump. If you have a pressure gauge between the last pre-filter and the high pressure pump, check its readings when the desalination plant fails to produce water. This way you can determine that the cause of the stop may be a malfunction of the high-pressure pump.

The high-pressure pump is a complex element of desalination equipment, which is better not to repair it yourself.

But here’s good news - this is the least problematic component of the high-pressure circuit. Problems may occur due to the failure of the plunger seals - in this case, you will notice water flowing out of the bottom of the pump. Replace the seals if you have spares.

Clogged check valves can also cause pump failure. They should be cleaned and reinstalled.

Poor Water Quality

If the quality indicators of the water produced by the watermaker do not correspond to the declared ones, you should first check the operation of your measuring instruments, unless, of course, you feel a drop in taste quality. Calibrate instruments appropriately.

If a change in water quality is noticeable even without indicators of measuring instruments, the reason for this can be either water intake in an inappropriate place (port, marina, region of high salinity of sea water, its high or low temperature) or problems with system elements.

High salinity or TDS levels may indicate that the deterioration of the membranes has reached the stage at which they allow the molecules of dissolved salts to pass through and not just pure water. When the membranes wear out, the salinity level changes very slowly and gradually. If this figure rises within a few days, you have encountered a very rare phenomenon - the failure of the membrane container. In both cases, membrane replacement is required.

Contaminated pre-filters or membranes can cause bad water odor. Microorganisms that settle on the membranes decompose without timely washing and become a source of hydrogen sulfide odor. Regular operation of the water maker, flushing the membranes with fresh water without chlorine after each use of the equipment will help to avoid this trouble.

Contamination of pre-filters and membranes leads to low feed water pressure, which can cause the system to shut down when the low-pressure switch is triggered.

System Leaks

Timely identification and repairing leaks in the system is a guarantee that it will maintain the pressure required for the declared performance of the device. And, as we have already found out above, the necessary pressure ensures the quality of desalinated water.

A leak in the system is signaled by the pressure level, which begins to gradually decrease compared to the declared one. A visual inspection is sufficient to detect leaks. But it is better, of course, to warn them in the course of regular preventive inspections of all connections and valves.

Only replacing damaged components will help to restore the pressure inside the system and its normal operation.

Unusual Noises or Vibrations

Loose or damaged components may cause unusual noise or vibration when the watermaker starts up. This evidence of a malfunction in the watermaker should by no means be neglected, since an improperly assembled system can be completely destroyed by vibrations.

For example, a whistling sound from the pressure supply unit (PSU) indicates problems with the supply pump - it is either running dry or the impeller has failed.

When unusual noises appear, the distiller must be stopped immediately. If the noise is caused by defective components, they should be identified and replaced. When loosening prefabricated elements, tighten the joints, if necessary, replace seals or fittings.

Vibration may be caused by air trapped in the system. First of all, this is noticeable if the high-pressure hose vibrates. This also requires immediate shutdown of the water maker as it can lead to failure of the high-pressure pump due to cavitation. If the high-pressure pump is not getting enough water, it can be caused by a clogged pre-cleaner system, as well as problems with the intake valve. Check and clean or replace pre-filters.

The reason for air being sucked in by the intake water valve may be its initial incorrect location above the waterline, as well as a strong roll of the vessel when the valve is above the water surface. But most often, as the experience of topRik experts shows, this phenomenon is caused by an incorrect position or clogging of the inlet 3-way valve. After setting it to the correct mode after precleaning, the problem disappears.

[vitrina]1631,1836,1828,1822,1812[/vitrina]

Electrical Issues

Faulty wiring or connections can cause power outages, bring the desalination system to a complete shutdown or even prevent equipment from starting.

If the watermaker does not start, check the power supply capacity or battery charge, fuel and oil levels (for different power sources).

Check all electrical circuit connections, repair them. Check capacitors and other elements, replace faulty ones.

Malfunctioning control panel or sensors also negatively affect the electrical system of the watermaker. These malfunctions are also dangerous by distorting the performance of the seawater desalination process. Therefore, these items should also be included in the preventive maintenance list, and the watermaker's electrical system should be checked regularly by a professional electrician.

Regular Maintenance and Prevention

No experienced sailor will question the importance of regular maintenance of all yacht systems, including the desalination system. This is a guarantee that on the high seas you will be protected from a significant number of problems that could become a threat to the health and even life of the inhabitants of the yacht.

Here are some preventive measures to avoid issues with your marine water maker:

- constantly keep the membrane wetted;

- rinse the membrane after each use of the desalination plant with clean fresh water without chlorine;

- do not allow the device to stand idle for more than 5 days (in the tropical regions - more than 3 days) in order to prevent overgrowing with salts and the reproduction of microorganisms;

- do not take water for desalination in marinas and ports, where it may contain oils, chemicals, biological contaminants;

- before long-term storage of the distiller in non-working condition, after washing with clean fresh water, treat the membrane with a biocide.

We also recommend that you strictly adhere to the preventive maintenance schedule, which includes inspection and maintenance of the watermaker's hydraulic and electrical systems, as well as all their components. If you follow these simple requirements, you will always have clean fresh water of excellent quality and in the required quantity on your yacht.

When to Seek Professional Help

When troubleshooting procedures fail, you should contact the specialists. These may be representatives of the manufacturing company or the company servicing your yacht.

The uninterrupted availability of high-quality fresh water on a yacht is a big safety concern. The lack of drinking water can lead not only to social issues between the participants of long-distance navigation, but also to their dehydration, which is extremely dangerous.

To avoid mistakes when choosing marine water maker for sale, use the recommendations of experienced yachtsmen of the topRik marketplace.