topRik experts explain how to maintain and staff a charter yacht before the start of the season, ensuring the safety and comfort for the renters. Our advice is intended not only for those who have just started renting out boats, but also for more experienced yachtsmen who use their vessel for commercial purposes.

Typically, only people with some experience start the charter business. For many of them, some aspects of preparing a boat for the season are a routine, familiar process. They typically have a good understanding and appreciation of their capabilities and technical skills, with several years of experience under their belt. That is why they may not pay attention to some problems with the equipment, sailing equipment or control system, being confident that if something happens, they can always make adjustments right at sea, because for this they have enough tools and spare parts on board, enough knowledge in their heads, enough dexterity in their hands.

We don’t know how justified this confidence is - all topRik employees are accustomed to preparing any boat (either their own or a charter one) for the season in strict accordance with internal checklists, which are developed on the basis of international conventions for commercial yachts. By the way, over the years some serious accidents did occur on ships captained by famous yachtsmen, although they know for sure that the words “the sea does not forgive mistakes” are not just an old platitude, but a harsh truth of life.

But in the case of miscalculations in the preparation of a personal yacht, the yachtsman risks his own health and life. It's a different story when you're preparing a boat for a skipper who may not have years of experience going to sea on his own. Of course, you will check all his permits and certificates, but they will only show the number of hours of practice at the skipper school under the supervision of instructors and, at best, the number of independent trips. The tenant's real yacht management skills are not reflected in any documents. Therefore, in order to ensure maximum safety of the client (regardless of his experience, by the way), and also your own legal safety, you need to prepare a charter yacht for the season much more carefully than even for yourself.

With this, we end the intimidation session and move on to practical advice. The first yachts of our fleet were built and purchased in 2014, since then the fleet has been replenished every year with sailing and motor monohulls and catamarans. And every year we prepare these boats for the charter season, so these recommendations are simply a condensation of many years of practical experience.

Preparation for the Next Season Begins at the End of the Previous One

It consists of preserving the boat for the winter, which should be preceded by a thorough cleaning of the yacht with the ruthless destruction of everything unnecessary that has accumulated in lockers, refrigerators and the hold.

Carefully examine the bottom of the boat, if necessary, carry out cleaning, puttying, painting and other procedures to restore sealing and smoothness of the surface.

Cover upholstered furniture with covers. Treat the seawater desalinator and preserve it. Then winterize the yacht.

Checklist for Technical Control and Pre-Season Yacht Maintenance

Mast and Rigging

Check all standing rigging connections.

The top of the mast is rarely paid attention to, although it performs several functions: it carries a backstay, a forestay, shrouds, a radio antenna, navigation lights, and halyard pulleys. Rotate the pulleys to ensure they are not misaligned or worn. Lubricate them with WD40 or silicon/vaseline based lubricant.

The spreaders, swivel, mast heel and blocks attached thereto, main sheet, toppin and their wiring blocks require checking for wear, damage or corrosion.

Check the presence/absence of galvanic corrosion at the joints of various metal parts.

Check the electrical connections and operation of the lights located on the mast.

Wax the grooves and bolt-ropes using candle wax or Teflon spray.

Standing rigging: look for areas where the cable is worn or twisted. Check the shroud shanks, T-joints, and rigging screws.

Service the furling drum and jib halyard swivel and check that they move freely. Typically the swivels become stiff and sometimes jam, which can cause damage.

Running rigging: check guide rollers for wear and jamming. Check the ropes for wear and tanning. If the ropes are salted, they can be washed in fresh water.

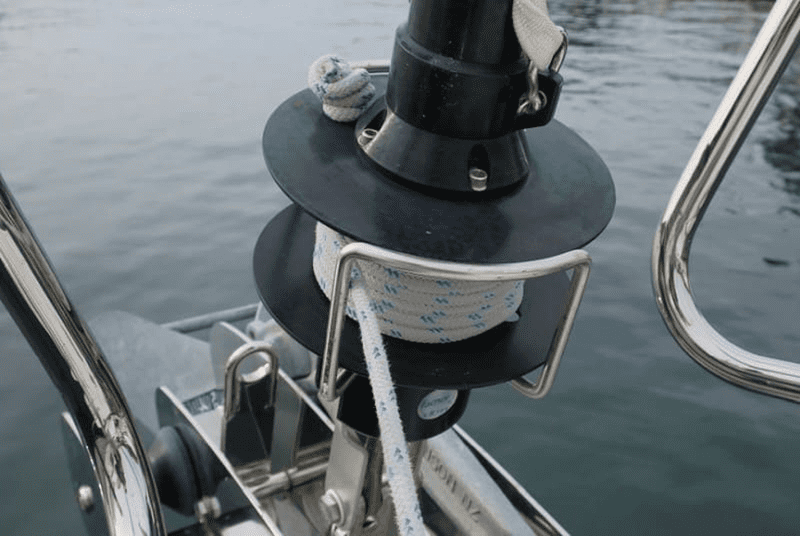

On Deck

Winches: disassemble, wash parts and lightly lubricate again.

Windlass: if manual, check operation, clean and tighten. If electric, check for water in the foot switch, clean and lubricate the remote control connector with contact grease.

Anchor chain: re-mark the length if it is faded or add chain markers. Check condition and wear.

Below Deck

Check the bilge pumps and their connections to the hoses.

Check the impellers and lubricate them with a special impeller lubricant (silicon/vaseline based lubricants destroy the impellers).

On an automatic bilge pump ensure the smooth operation of the float switch.

Dry the bilge thoroughly. Then, if water appears after launching, you will know that you have a leak.

Add purifier to the water tank.

If the latrine pump is running slowly, perform maintenance and lubricate the parts with silicon/vaseline-based lubricant.

If you have a gas sensor, check its operation.

Below the Waterline

Check the clamps for rust.

Most ships have seams made of dezincification-resistant brass. Look for any signs of corrosion on the plating and tail joints, which are the main problem areas.

Make sure all valves are lubricated.

All hoses must have double clamps. Check the clamps for rust.

You should have a set of plugs in case of emergency.

Make sure fittings are not corroded, damaged or fouled.

Check the condition of all anodes: motor, heat exchanger, gearbox, housing, shaft and propeller.

Inspect the entire surface of the rudder blade for damage or microcracks.

Check for play in the baller. Movements should be minimal. Lubricate the steering cable.

To check the bearings, grasp the support with both hands and try to move it up and down and from side to side. There should be little movement, if any, no more than 2 mm.

Make sure there are no cracks or displacements, especially at the keel attachment point, outside and inside the boat. Check the shaft bracket and liner for integrity, cracks and damage.

Another thing to worry about is deadwood. Different yachts have different sternwood designs, but on average their service life is about seven years. Lubricants should be added to the packing gland to prevent drying out and brittleness. In some cases, the oil seal needs to be replaced.

If you have an S-drive , check the condition of the gasket and the metal ring holding it in place. Again, note that gaskets have a life expectancy of five to seven years depending on the manufacturer.

Machinery Maintenance

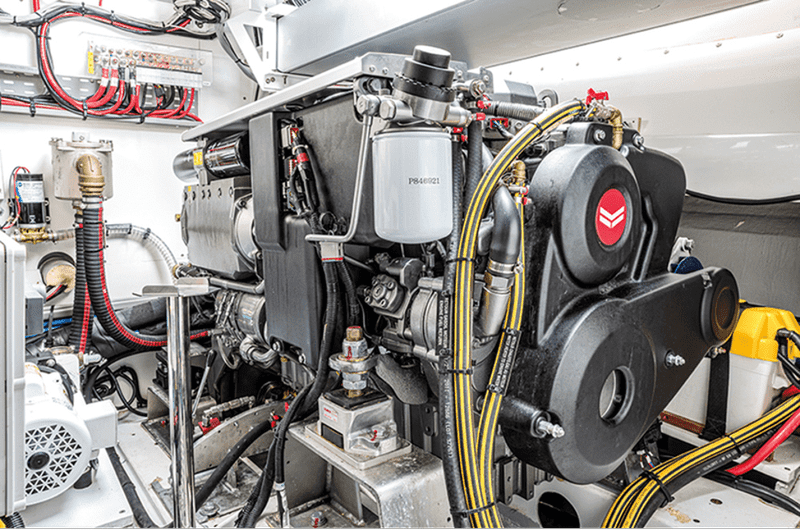

Engine

Replace all oil filters. If you didn't change your oil at the end of the season before climbing, change it now. Replace fuel filters. Remove rags from the exhaust pipe if they were installed for insulation.

Replace impellers. If they were removed when storing the engine for use next season, reinstall them using a special impeller lubricant. We also recommend replacing the impeller cover gasket.

Check the engine belts and their tension: the deflection should not exceed 1-1.5 cm.

Inspect the level and quality of antifreeze. Replace if necessary.

Saildrive

Check the oil levels. Check the condition of the gaiters (cover). Check the condition of the membrane and seal if necessary.

Replace the motor anode. Check that the engine is securely mounted.

Inspect the diesel tank for condensation water. Drain or replace fuel. Add an appropriate biocide to kill the diesel bug.

Take a look at the wiring, such as the connecting wires from the anode and the ground wires from the starter. Clean the terminals and lubricate them with contact lubricant.

Batteries and Electrical Systems

Test the electrolyte level if you have a lead-acid battery; tighten the battery straps and make sure the gas vent is not clogged. Clean the terminals and lubricate the contacts. For sealed batteries, check the status of the charge indicator light or other charge sensor.

Turn on appliances and their lights to reduce accumulated condensation.

If the anode looks good for next season, check its connections and wires. If the anode is not worn at all, it may not be working, so check the maximum resistance (0.2 ohms) from the screw to the anode.

Sails

Check for fraying, loose seams and tears. Check for a sail repair kit.

Take it to a sailmaker if you cannot repair the damage to the sails yourself.

Devices

Make sure your navigation apps are up to date. For electronic cards, see the User's Manual on how to update them - new chartplotters can connect to Wi-Fi for this. On simpler models, to update maps, you will need to remove the memory card, connect it to your computer and download updates from the map publisher's website.

Download software updates for your chartplotter and instruments.

Make sure your phone and tablet navigation app subscriptions are up to date.

Safety

Gas System

Pay attention to the age of the hoses. If they are more than five years old, they should be replaced. Check gas hoses for kinks or wear. When in doubt, replace.

Vefify the tightness of the hose clamps. Hoses behind the slabs must be reinforced.

Ensure the proper operation of the thermal switches on the stove, grill and oven.

Harnesses and Buoys

Inspect the seams and contact a repairman if necessary.

When it comes to storm rail (Jackstay or Lifeline) and rescue system type DAN BUOY MOB: check the condition and reliability of fastening on the deck.

MOB Lights

If you have a traditional model, check the bulb, battery and make sure it actually works. New models have different testing methods and they all have an expiration date.

Life Jackets

Check that your life jackets are suitable for use and that they are in good condition. If you have automatic life jackets, have them serviced. Inflate them using a mouth tube. Leave them inflated overnight to check for leaks and rinse with fresh water if necessary. Take a look at the lights if installed.

Railing Fencing

Inspect the railing posts to ensure that the railings are in order and securely fastened at both ends. Check that the plastic sheath of the cable is not damaged.

Flares

Make sure that the flares have not expired, are stored in a waterproof container and are located in an easily accessible place. It's also a good idea to have gloves and safety glasses on hand.

EPIRB

Make sure they are up to date and registered with the correct contact details.

Life Raft

Check the period of maintenance and re-stowing of the raft. Make sure that the crew knows the rules of its operation. If the raft is secured to the deck or transom, consider whether it can be easily unfastened in an emergency. Pack a bag with essentials.

First aid Kit

Make sure you have the first aid kit on board for completeness. All its components have an expiration date - replace drugs that have expired.

If your yacht is parked in Croatia or Montenegro, you can always enlist the help of experienced yachtsmen at SimpleSail. Call the specified phone number, use the site’s quick contact form or send a request to [email protected].

We remind you that topRik Group also provides charter management company services, which include preparing commercial yachts for the season. You can find out more about it here: