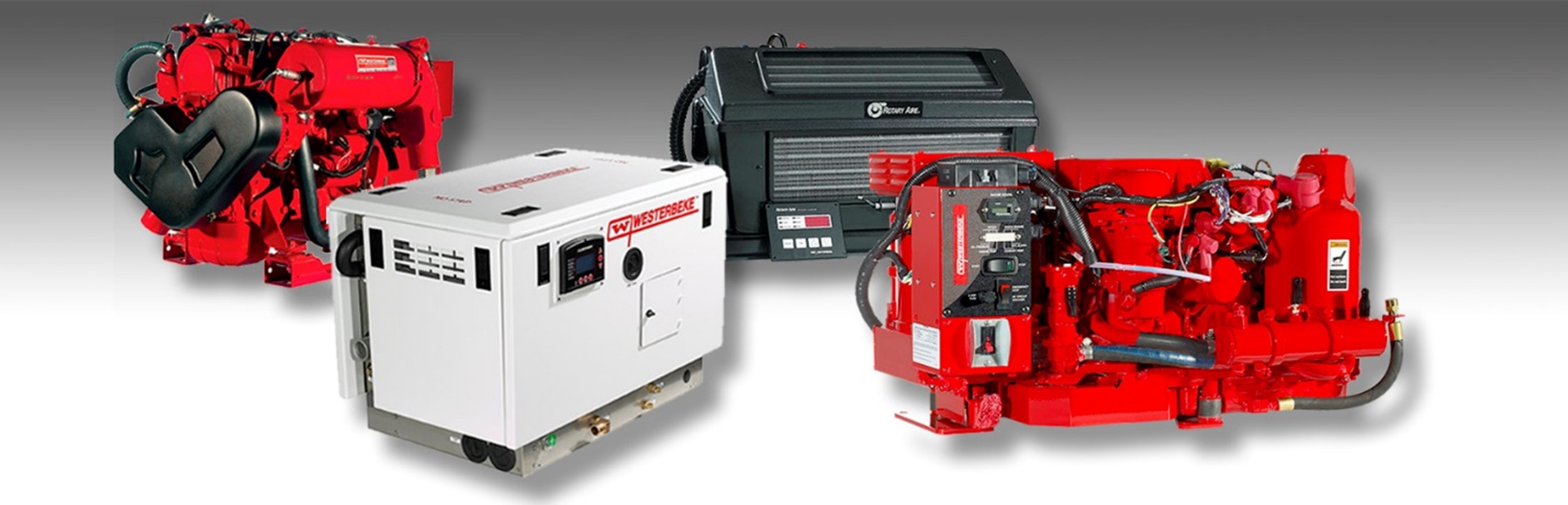

topRik experts share their experience of using different types of generators on yachts and boats of different sizes and configurations. How can you tell if your boat generator has started to overheat? Is it even possible to avoid overheating of a generator on a boat? We answer these and other questions by looking at the different types of yacht generators.

Based on many years of practice, we have selected for you models of marine generators that meet all safety requirements, are simple and reliable in operation. In addition to generators, the topRik marketplace also offers accessories and additional equipment that optimize the operation of your yacht's electrical system.

Causes of Generator Overheating

As we have already said, and most sailors know this from practice, small vessels use direct and alternating current generators. DC generators are most often used on stationary and outboard boat motors. Alternators are an alternative power source that can be fueled with either gasoline or diesel fuel. These generators can be portable or stationary.

It is quite clear that each of the types of generators used on a yacht may have different breakdowns that lead to its overheating. But there are a number of violations during the installation and operation of generators of various types, which are common and lead to overheating of the generator on the yacht.

There are also those that are characteristic only of a certain type of yacht generators. For example, an automotive-type generator set, which is most often used on inboard and outboard boat engines, consists of several main parts - a three-phase generator, rectifier diodes and a regulator. The generator produces alternating voltage, diodes convert it to direct voltage, and the regulator, as its name suggests, maintains a given voltage level, despite changes in load, temperature and engine speed.

The target voltage of a typical regulator is 14.4 volts, which is the same as the absorption voltage for some types of deep cycle batteries. Absorption is a charging phase at a constant voltage during which the internal areas of the battery plates are restored and the battery charge reaches its maximum value. The duration of absorption depends on the initial condition and type of battery and ranges from 30 minutes to 8 hours.

As the charge of the battery increases during the absorption process, the current consumed by it decreases. After the current drops to 3-5% of capacity, the battery is considered charged. At this point, the charger must reduce the voltage so as not to overcharge the battery. The generator regulator cannot lower the voltage, so even a fully charged battery remains under increased voltage throughout the entire engine operating time.

The current flowing through a charged battery heats it up, and the temperature of the battery gradually begins to rise. As the temperature rises, the rate of chemical reactions increases and, if the charging voltage is not reduced, intense gas formation will begin to squeeze the active material out of the plates and destroy the battery.

Problems may also arise with the generator itself. A discharged high-capacity lead-acid battery or a LiFePO4 battery with a capacity greater than the generator's rating will cause the generator to operate at full power for a long time. After some time, it will heat up and, if the cooling is insufficient, it may burn out.

Most ships have not one, but at least two batteries - a starting battery and a service battery. The starter should not have any other load other than the engine starter, so all on-board equipment - navigation devices, lighting, refrigerator, multimedia, etc. connected to the service battery. On boats with a thruster and/or electric winches, a third battery may be installed at the bow.

Typically, on a large vessel with a significant amount of electrical equipment, it is powered by a stand-alone diesel generator. That is, the same problem can arise with stationary alternating current generators if the condition of the batteries is not monitored. For such monitoring, the topRik marketplace offers equipment of varying levels of complexity, designed for different types and numbers of batteries: battery monitoring, autonomous digital control panels, monitoring systems with full integration into the yacht’s electrical system, digital switching systems, in particular – digital panels of the Simarine Nereide switching system and similar.

Next, we will talk about the causes of overheating, common to all types of boat generators, both direct and alternating current, both stationary and portable, both diesel and gasoline.

Improper Installation or Ventilation

Installation errors and ventilation problems can cause overheating of both gasoline and diesel generators. Actually, installing a portable gasoline generator means installing it in a well-ventilated area and connecting it to an electrical device - a power consumer. In a yacht, the ideal place to install a portable gasoline generator can only be on the deck, where excellent ventilation will be provided. In any other room of the yacht, especially if the sailing region is a water area with a hot climate, there is a risk of increased heating of the generator simply due to the high temperature in the room. We don’t even mention the exhaust that is hazardous to health, which precludes the operation of this equipment in enclosed areas of the ship.

If we are talking about stationary equipment, then you should choose models where ventilation is provided by the design of the generator itself. For example, the cooling system of Mase generators presented in our marketplace consists of an air/seawater heat exchanger. Air flows provide efficient cooling, optimal temperature for better generator performance and reliability. This system ensures better operating conditions for the generator set, regardless of the room temperature.

However, even this design requires that during installation there be sufficient space around the generator to ensure good air circulation.

Generator Overload

The result of overloading the generator with starting and traction batteries was described above when excessive heating of the batteries causes the generator to overheat. But if you control the temperature of the batteries through special devices - a battery monitor, a battery control panel, battery monitoring systems, etc. – then overheating is excluded. Typically, such monitoring devices are equipped with an alarm sound or video signal.

Overloading of a gasoline portable generator can be caused by exceeding the permissible operating time, as well as by high outside temperatures - gasoline portable models do not have a protective casing or any heat exchange systems.

Lack of Coolant

It is necessary to update the coolants in the generator on time to avoid significant breakdowns. They ensure uninterrupted operation of the device and protect it from overheating.

The fuel combustion process occurs at high temperatures. Heat is generated by friction of contacting parts. If there is not enough coolant, the elements of the unit will overheat, which will lead to rapid wear of parts, shortening the life of the electric generator, jamming of its engine and the appearance of carbon deposits that worsen the combustion mode.

The end result will be a significant breakdown of the diesel or gasoline generator and expensive repairs or the purchase of a new one. The cost of coolant is significantly lower. It is important to regularly add antifreeze to ensure proper levels in the generator fuel system.

Cooling System Contamination

Cooling in electric generators can be air or liquid.

The air type of cooling has a fairly simple design and has low heat removal capabilities, so they are usually installed only on low-power generators, up to 20 kVA. The principle of operation is as follows: the influx of fresh air, which passes through the heated parts of the equipment, cools them. Therefore, it is recommended to install such electric generators outdoors or equip them with supply and exhaust ventilation.

The advantages of an air-cooling system for generators are:

- compactness of the unit and ease of maintenance;

- moderate cost, which is logical due to the simplicity of execution;

- low vibration level;

- rapid achievement of operating temperatures, which in due course increases efficiency;

- the presence of a piston system, which is distinguished by excellent wear resistance and high temperature tolerance.

The disadvantages of electric generators with an air-cooling system include the fact that such units can only be used as a backup power source, as well as a limited resource and operating time.

Electric generators with liquid cooling provide a much longer operating life, and therefore such stations can even be used as the main power source.

Structurally, the liquid cooling system is represented by a cooling jacket, a radiator with an expansion tank and a steam-air valve, a refrigerant pump, a thermostat, a fan and connecting pipes.

Antifreeze is usually used as a coolant, but other chemical compositions specified by the manufacturer can also be used.

Unfortunately, ignoring the manufacturer's recommendations can lead to breakdown of the system and the generator itself.

To prevent corrosion of engine elements and prevent scale formation, it is recommended to use special additives, which is also a common violation on the part of generator users.

The operating principle of the liquid cooling system is similar to those used in modern cars. The engine drives a pump that circulates coolant. Until the fuel-generating parts heat up, the liquid moves in a small circle, bypassing the radiator. As the temperature of the internal elements of the generator increases, the refrigerant begins to circulate in a large circle. The fan provides a constant flow of air, thereby cooling the liquid in the radiator.

The advantages of this type of generator cooling include the following:

- maximum reliability and durability thanks to thermostats that regulate the degree of cooling and a steam-air valve that releases the steam generated;

- possibility of operation in unfavorable and extremely harsh conditions;

- unpretentiousness to the quality of the fuel used and the level of service.

As is clear from the description of the operating principle, any clogging or other disturbances in the air- or water-cooling system will lead to overheating of the generator.

We remind you that in the topRik marketplace we have selected for you models with air-liquid cooling: the cooling system of such diesel generators consists of an air/seawater heat exchanger.

Wear of Generator Components

The main components of a diesel generator are:

- diesel engine with life support systems - air and fuel supply systems, cooling system;

- alternating current generator (asynchronous or synchronous);

- automatic monitoring and control system for diesel generator;

- frame for installation and fastening of equipment, which can be supplemented with a casing for noise absorption and protection from environmental influences.

The quality of spare parts directly affects the durability and reliability of the diesel generator. Poor quality, worn parts can lead to rapid wear of contacts, causing sparking or corrosion.

The use of low-quality spare parts often causes delays in starting the generator, which can be critical in some situations.

In order for your diesel electric generator to serve for a long time and trouble-free, it is important to pay attention to the operating rules, carry out regular maintenance and use only high-quality spare parts, replacing worn-out ones on time.

Signs of Generator Overheating

Here we will first of all talk about the symptoms of overheating of a stationary generator, which, as a rule, is connected to traction batteries as an alternative power source. Signs of a portable generator overheating include smoke, process interruption, or complete shutdown.

Visual and Audible Overheat Warnings

If you are serious about the safety of the electrical equipment on your yacht, you will of course have a battery monitoring system installed. As a rule, these systems, which can be either a separate battery monitor or a complex communication system with a digital control panel, are configured to the extreme temperature limits of the batteries. Using a relay, when the control indicators are reached, the system gives an audible or visual alarm. And we already know what overheating batteries means for a generator.

Reduced Generator Performance

If such a monitoring system is not installed, then problems with the generator can be tracked by monitoring its performance. But here is the problem: in addition to overheating, the generator’s performance may be reduced by other problems.

Generator Shutdown or Emergency Stop

The generator can be turned off either manually using a battery disconnect switch or using a monitoring system. In the first case, it will be an emergency stop, when there is no doubt about a malfunction in the yacht's power supply system.

But this situation can be prevented by installing monitoring equipment in the yacht’s electrical system, which will monitor the condition of the batteries, which are charged using the generator’s energy. If the temperature regime is violated, the operation of the generator will be stopped. Or, depending on the programmed algorithm, a signal about a critical violation of the temperature regime will be given.

The table below shows the most typical problems of diesel generators of different categories by power and design, as well as ways to eliminate them. Why diesel? Because they are the most common type of marine generators and are used on yachts of different sizes and configurations.

|

Problem |

Possible reasons |

How to fix the problem |

|

Engine won't start |

Worn or discharged battery |

Check the battery charge and replace it if necessary |

|

Starter problems |

Check the starter and replace damaged parts |

|

|

Incorrect wiring connection |

Recheck all connections and repair possible damage |

|

|

Frozen fuel |

Defrost the fuel system using appropriate methods |

|

|

Clogged fuel filter |

Replace or clean the fuel filter |

|

|

Engine cranks slowly |

Low battery level |

Charge the battery or replace it |

|

Viscous engine oil at low temperatures |

Check the viscosity of the oil and replace it with a suitable one |

|

|

Starter relay problems |

Check and replace starter relay if necessary |

|

|

Problems with bearings or internal engine parts |

Diagnose the engine and replace damaged parts |

|

|

Engine won't stop |

Malfunction of the diesel generator set (DGS) control system |

Check and, if necessary, replace the control unit or individual components of the control system |

|

Stuck fuel valve |

Diagnose and repair or replace the fuel valve |

|

|

Trip mechanism malfunction |

Check the shutdown mechanism and repair or replace it |

|

|

Engine overheating |

Lack of coolant |

Check the coolant level and top up if necessary. Check the system regularly for leaks. |

|

Clogged radiator |

Clean the radiator from dirt and foreign objects. If necessary, contact a specialist for deep cleaning. |

|

|

Faulty thermostat |

Check the functionality of the thermostat and replace it if defects are detected. |

|

|

Inefficient water pump operation |

Diagnose the water pump and repair or replace it if a malfunction is detected. |

|

|

Problem |

Possible reasons |

Solutions to the problem |

|

Oil pressure in the diesel generator is too high |

Using the wrong type of oil |

Make sure you are using the correct type of oil designed for your diesel generator and change the oil if necessary. |

|

Oil filter clogged |

Clean or replace the oil filter to restore normal oil pressure. |

|

|

Faulty oil pump |

Check the oil pump and if a malfunction is detected, repair or replace it. |

|

|

Too much blue smoke from diesel generator |

Increased oil consumption |

Check the oil level and repair any leaks. Replace piston rings if necessary. |

|

Faulty or clogged injectors |

Diagnose and clean the injectors and, if necessary, replace them with new ones. |

|

|

Clogged air filter |

Check the condition of the air filter and replace it if necessary. |

|

|

Malfunction of the fuel injection system |

Conduct diagnostics of the fuel injection system and eliminate any detected faults. |

|

|

Too much white smoke from diesel generator |

Low engine temperature |

Allow the engine to warm up to normal operating temperature before operating. |

|

Penetration of antifreeze into the combustion chamber |

Check the condition of the head and cylinder gaskets. Replace them if necessary. |

|

|

Incomplete combustion of fuel |

Check the fuel supply system and diesel generator settings to ensure complete fuel combustion. |

|

|

Presence of water in fuel |

Ensure high-quality fuel filtration to remove moisture and other impurities. |

|

|

Too much black smoke from diesel generator |

Excess fuel in the combustion chamber |

Check and adjust the fuel supply system to ensure proper fuel/air mixing. |

|

Clogged air filter |

Clean or replace the air filter to ensure the proper amount of air mixes with the fuel. |

|

|

Faulty turbine |

Conduct diagnostics of the turbine and, if necessary, repair or replace it. |

|

|

Worn or damaged injectors |

Check the condition of the injectors and, if necessary, repair or replace them. |

|

|

Diesel generator oil consumption is too high |

Wear of engine parts |

Conduct engine diagnostics and replace worn parts. |

|

Wrong oil |

Make sure you use the oil recommended by the manufacturer. |

|

|

Oil leakage from seals or gaskets |

Inspect for leaks and replace damaged seals or gaskets. |

|

|

Clogged or damaged air filter |

Clean or replace the air filter to ensure proper air pressure in the system. |

|

|

Problem |

Possible reasons |

Solutions to the problem |

|

Diesel generator fuel consumption is too high |

Incorrect engine settings |

Carry out diagnostics and adjustment of engine settings. |

|

Worn or damaged parts |

Inspect and replace worn or damaged parts. |

|

|

Fuel system clogged |

Clean the fuel system from scale and blockages. |

|

|

Incorrect fuel system pressure |

Check and, if necessary, adjust the pressure in the fuel system. |

|

|

Insufficient diesel generator power |

Air filter clogged |

Clean or replace the air filter. |

|

Use of low-quality fuel |

Replace fuel with quality fuel. |

|

|

Problems with the fuel system |

Diagnose the fuel system and correct any problems found. |

|

|

Worn engine parts |

Inspect the engine and replace worn parts. |

|

|

Diesel generator works intermittently |

Dirty fuel filters |

Clean or replace fuel filters. |

|

Unstable electrical connection |

Check all electrical connections and correct any problems. |

|

|

Incorrect generator settings |

Check and, if necessary, adjust generator settings. |

|

|

Problems with the fuel pump |

Check the functionality of the fuel pump and, if necessary, replace it. |

|

|

The alternator does not produce voltage (no-load voltage is 10% lower than the nominal voltage) |

Damage to the alternator windings |

Check the windings for damage and replace them if necessary. |

|

Faulty voltage regulation system |

Check and adjust the voltage regulation system; the regulator may need to be replaced. |

|

|

Problems with rectifier diodes |

Check the rectifier diodes and replace damaged ones. |

|

|

Poor contact or contact oxidation |

Check all contacts for oxidation or poor contact, clean and tighten them. |

|

|

The alternator does not generate voltage (no-load voltage is 20-30% lower than the nominal voltage, the voltage does not respond to rotation of the AVR potentiometer) |

Faulty AVR potentiometer |

Check the AVR potentiometer for faults and replace it if necessary. |

|

Damage to the alternator windings |

Check the windings for damage and, if necessary, repair or replace them. |

|

|

Voltage regulation system faulty |

Conduct diagnostics of the voltage regulation system; if faults are detected, replace damaged elements. |

|

|

Problems with rectifier diodes |

Check the rectifier diodes and replace damaged ones. |

|

|

The output voltage of the diesel generator is 50-70% of the nominal |

AVR malfunction |

Check the automatic voltage regulation (AVR) unit and replace it if necessary. |

|

Damage to generator windings |

Perform a visual inspection and test the generator windings for short circuits or open circuits. If damage is found, repair or replace. |

|

|

Problems with generator excitation |

Make sure the excitation system is functioning correctly. If necessary, adjust system parameters or replace faulty components. |

|

|

Rotor or stator malfunction |

Check the condition of the rotor and stator. If wear or damage is found, repair or replace parts. |

|

|

Problem |

Possible reasons |

Solutions to the problem |

|

Diesel generator output voltage too high |

Malfunction of voltage regulator (AVR) |

Check and, if necessary, replace or reconfigure the voltage regulator. |

|

Inadequate load |

Make sure the diesel generator is running at a load that matches its capacity. If necessary, connect additional consumers or reduce the load. |

|

|

Sensor malfunction |

Check the generator sensors for malfunctions. If problems are found, replace the sensors. |

|

|

Damage to generator windings |

Carry out diagnostics of the generator windings. If defects or damage are found, contact the service center for repair or replacement of components. |

|

|

Unstable output voltage of diesel generator |

Load fluctuations |

Stabilize the load, eliminate overloads and short-term load drops. |

|

Malfunction of voltage regulator (AVR) |

Check and, if necessary, replace or reconfigure the voltage regulator. |

|

|

Wear or damage to the generator windings |

Check the windings and repair or replace them if damaged. |

|

|

Problems with the fuel system |

Diagnose the fuel system, clean or replace filters, and repair fuel leaks. |

|

|

Diesel generator does not reach operating speed |

Incorrect control system setting |

Check and adjust control system parameters following manufacturer's instructions. |

|

Fuel system clogged |

Clean the fuel system, including filters and fuel pumps, of contaminants. |

|

|

Turbocharger malfunction |

Diagnose and repair or replace the turbocharger. |

|

|

Worn or damaged engine parts |

Carry out a thorough inspection of the engine, replace worn or damaged parts. |

|

|

Diesel generator does not hold load |

Generator overload |

Make sure that the load on the generator does not exceed its rated capacity. Distribute the load evenly. |

|

Faulty cooling system |

Check and clean the cooling system. Replace the radiator or thermostat if necessary. |

|

|

Fuel system clogged |

Clean and check fuel filters and pumps, remove blockages in the fuel system. |

|

|

Incorrect engine settings |

Check the engine settings and adjust them according to the manufacturer's recommendations. |

|

|

Problem |

Possible reasons |

Solutions to the problem |

|

Diesel generator does not produce voltage |

Faulty Automatic Voltage Regulator (AVR) |

Check the AVR for damage and replace it if necessary. |

|

Break in the wiring |

Check all connections and wiring for breaks or short circuits. If necessary, repair or replace wires. |

|

|

Damage to generator windings |

Inspect the windings for damage. The windings may need to be repaired or replaced. |

|

|

Faulty diode bridge |

Check the diode bridge for damage and replace it if necessary. |

|

|

Diesel generator voltage fluctuates |

Unstable engine operation |

Check the fuel supply system and eliminate possible faults. Engine adjustment may be required. |

|

Worn or faulty automatic voltage regulator (AVR) |

Check the condition of the AVR and replace or adjust it if necessary. |

|

|

Damage to the alternator windings |

Check the alternator windings for damage and repair or replace them. |

|

|

Fluctuations in load |

Troubleshoot any problems with equipment connected to the generator that may be causing load fluctuations. |

|

|

Diesel generator stalls during operation |

Incorrect fuel system settings |

Check and adjust fuel system parameters, including fuel pressure, injectors, and fuel lines. |

|

Air filter clogged |

Clean or replace the air filter to ensure normal air intake pressure. |

|

|

Engine overheating |

Check the cooling system for blockages or leaks and repair them if present. |

|

|

Electrical problems |

Check the integrity of the electrical system, including the battery, ignition, alternator. |

|

|

Loud knocking noises when operating a diesel power plant |

Wear or damage to engine parts |

Conduct engine diagnostics and replace worn or damaged parts. |

|

Fuel system malfunction |

Check and adjust the fuel system; filters or injectors may need to be replaced. |

|

|

Pulley or bearing problems |

Inspect the pulleys and bearings and replace them if necessary. |

|

|

Foreign objects entering the engine |

Carry out a thorough check of the engine for foreign objects and remove them. |

FAQ

What to do if the generator on the yacht starts to overheat?

Depending on the model of the generator and the consumers it serves, check the condition of the batteries if it is a stationary diesel generator that powers the boat's traction batteries. If necessary, replace faulty batteries. We remind you that in the topRik marketplace you can buy batteries for a yacht from the world's most popular manufacturers of marine electrical equipment.

If the batteries are OK, check the ventilation system, cooling system, fuel supply, as well as the condition of the contacts, the presence of corrosion at the wire connections.

If it is a portable generator, it may be due to overrunning, so just check it after it has been turned off and cooled down completely. If it is overheating during the normal operating time, check the ventilation, cooling, fuel supply and connections.

How to choose the right coolant for a generator?

Generally, the generator manufacturer's recommendations should be followed; serious marine electrical companies must include this information in their operating instructions.

What preventive actions will help avoid generator overheating?

Regular maintenance of any type of generator in strict accordance with the requirements of the operating instructions will save their owners from problems with overheating.

If we are talking about a stationary diesel generator, then we need to start with proper installation. We highly recommend installing a specialized battery monitoring system, at least the most basic one, in the form of a battery monitor, rather than relying on a voltmeter or ammeter.

What you need to pay attention to when optimizing the charging process from the engine generator (alternator), which is usually limited to racing enthusiasts whose goal is to make the boat as light as possible:

- the alternator in a hot state and at operating speeds should be about 15-20% of the capacity of the service batteries;

- for high-capacity battery packs, it is advisable to have an external smart controller with temperature sensors for the alternator and battery;

- check the voltage drop between the alternator and the battery terminals;

- ensure good ventilation of the engine compartment and batteries;

- check the voltage drop across the diode divider;

- check the voltage at the alternator terminals with a fully charged battery, it should be close to 14.4V. but not more than 14.7V.

Controllers, inverters, specialized chargers - all this equipment can significantly protect your yacht's electrical system as a whole, and not just the generators installed on board.

topRik marketplace experts will help you for free to equip your yacht with an efficient and economical electrical system, which will make the longest autonomous passage safe and comfortable.