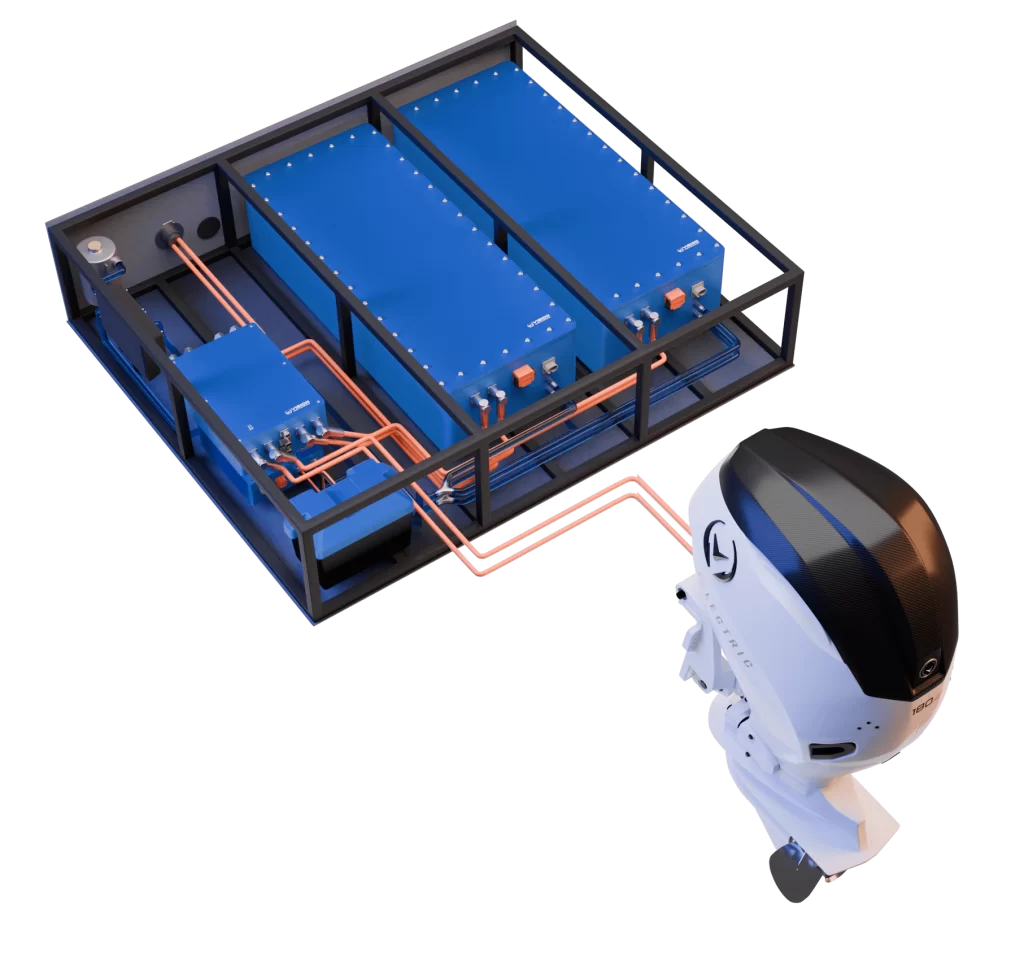

Vision Marine Technologies has teamed up with Calip Group to manufacture custom cooling plates for its high-voltage marine battery packs.

Under the partnership, Calip Group will provide components to improve the thermal management of Vision Marine's high-voltage marine battery packs.

These custom cooling plates are specifically crafted for marine applications, with a dedicated production line established and manufacturing scheduled to commence in 2025.

"Dealing with overheating issues in high-voltage marine batteries poses a significant challenge," explained Xavier Montagne, the technical director of Vision Marine. "In response, we have developed specialized cooling plates to enhance the stability of the battery pack and improve its thermal efficiency."

Montagne highlighted that marine battery packs operate in demanding environments that require sustained high-power delivery over prolonged periods. Unlike most high-voltage batteries designed for brief power bursts, marine applications subject batteries to thermal stresses that can degrade cells and reduce their lifespan.

To tackle these issues, Vision Marine has created cooling plates tailored to meet the unique thermal demands of marine battery packs. These plates enhance heat dissipation, stabilize cell temperatures, ensure consistent performance, improve reliability, and prolong the cells' operational lifespan.

"We have adjusted our industrial tooling to match the specific requirements of the battery and its assembly process," stated Thierry Giorgalla, the general director of Calip Group. "Through significant investments in refining our Friction Stir Welding (FSW) method, we can produce fully sealed cooling plates with precision, meeting tight tolerances. Calip Group stands out as one of the European leaders in mastering this sophisticated process."

Vision Marine's battery packs boast IP67-rated stainless steel construction, advanced thermal management systems, and modular configurations tailored for boats ranging from 18 to 34 feet in length.

Calip Group's Friction Stir Welding process has been specifically developed to facilitate the precise manufacturing of fully sealed cooling plates.

Vision Marine owns the tooling outright, maintains strong production partnerships, and plans to expand its manufacturing operations. The production agreement with Calip Group represents a strategic move to address the increasing market demand for high-performance electric boating technologies.