Digital or mechanical? topRik experts help you figure out when digital switches are preferable to mechanical ones. Our marketplace provides a large selection of digital and mechanical battery switches. Our team constantly tests the work of both in practice, both on yachts and on our camper.

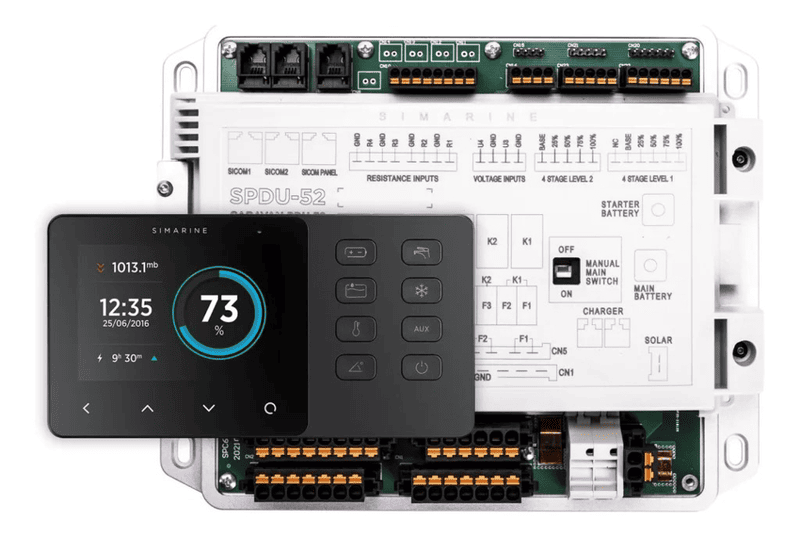

This review will highlight the benefits you get if your yacht allows you to install a digital monitoring system with a switchboard control panel similar to the Via set, Nereide 2 Set by Simarine, CANvu Victron GX Energy or others, which you can easily find in our marketplace in the relevant sections dedicated to marine electrical equipment and its manufacturers.

First, let's look at the types of marine batteries, and the principles by which the load on batteries is distributed according to their type of chemistry and purpose. This is necessary in order to evaluate the volume of tasks that digital battery switches have to evaluate and what additional functions they must perform. Because both the comfort of operating the yacht and the convenience for everyone on board, as well as the maximum level of navigation safety, depend on this.

On boats, yachts and other types of water equipment, 2 types of motors are used: internal combustion engines and electric motors. Internal combustion engines allow you to quickly move across bodies of water, and electric motors are environmentally friendly and quiet. Internal combustion engines only need a power source for starting, while electric motors need a constant source of energy during operation.

Therefore, watercraft use both starter batteries, which are similar in operating principle to automobile models, and traction batteries, designed for intensive use in cyclic mode. It all depends on the type of motor.

Marine-type batteries - starter and traction, with any type of chemistry - are adapted for use on yachts, boats and other watercraft. They have a sealed body and a high level of moisture resistance, are not afraid of shaking, vibration and roll, are not prone to leakage of electrolyte or shedding of plates and can work in a position on their side. Such drives are designed for harsh operating conditions and are therefore produced using special technologies.

Even marine-grade lead-acid batteries feature an advanced, maintenance-free design with thicker plates, a gel electrolyte, a durable sealed casing, and special additives that resist oxidation and chemical degradation. Lithium batteries are even more different from car batteries. They are compact and lightweight, but at the same time accumulate a large amount of energy and provide stable power to electric motors. Such batteries consist of individual batteries connected into a single system and equipped with a BMS protection board.

Batteries of the LiFePO4 subtype - lithium iron phosphate - are best suited for powering boat electric motors. These are traction batteries with a stable chemical structure and a long cyclic life. They are not afraid of deep discharges, work stably even in cold and hot weather, do not ignite even in emergency situations and perform more than 2000 charge-discharge cycles.

To start the engine, a high current must be supplied to it for a short time, which is what the starter battery does in a car or other vehicle. After this, he rests and restores spent energy. A traction battery works differently: it produces much lower currents, but continuously, as long as a load is connected to it. As a result, the battery is discharged - it releases most of the accumulated energy, and then replenishes it when charging from the mains.

Such power supplies operate in a cyclic charge-discharge mode, and even their service life is measured by the number of operating cycles. The most important characteristics of such batteries are:

- energy-to-weight ratio – the volume of accumulated energy;

- permissible charge and discharge currents;

- cyclic resource;

- resistance to deep discharges.

Additional requirements are put forward for marine batteries: low weight with a large supply of capacity, moisture protection, resistance to atmospheric factors, roll and pitching, the presence of an impact-resistant case, a comfortable handle and a carrying strap.

Digital Battery Switches Basics

Digital switches are a combination of 12 V power distribution devices (DC, AC, remote switches) and a switchboard control panel. These devices allow you to monitor the condition of batteries installed on a ship or vehicle, as well as program their switching scheme without using manual switches.

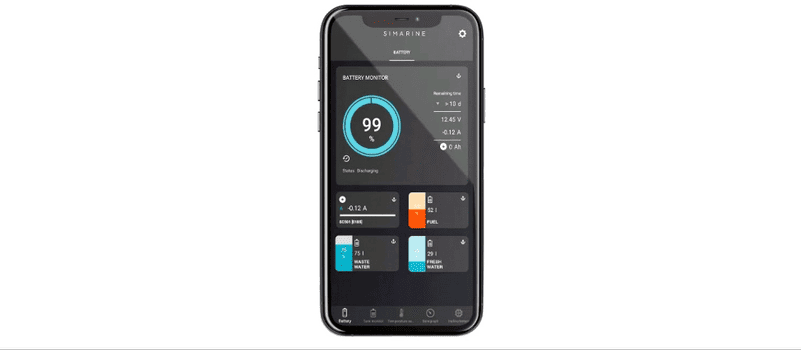

With the help of a special application, you can perform all these tasks from your smartphone, while being anywhere in the world.

For example, it occurred to you to take a walk after a busy day at work. You open the application, check the condition of the batteries of your yacht, which is parked at the pier and charge them to the level you need, turn on the air conditioning so that the temperature in such heat (let's say!) becomes comfortable before your arrival, or program the coffee maker for a cup of coffee according to your favorite recipe.

Arriving at the pier and getting on board, you pick up the prepared coffee or a chilled drink and while standing at the helm after starting the engine, you set the time for turning on the ship's lights and your sound system.

All this time, the intelligent monitoring system monitors the condition of all types of batteries that are connected to the system through shunts, gateways and modules, ensures their safe switching and shutdown, data on these measurements and actions is displayed on the switch panel screen.

Predecessors of digital switches were mechanical battery switches, with which almost any owner of a motor boat or yacht is very familiar. Because, despite the commitment to innovative digital technologies, experienced sailors do not abandon the classic magnetic compasses, paper charts, manual switches and battery switches.

The idea of switching batteries in electrical circuits also did not appear immediately, but only as these circuits became more complex and branched.

At first these were two-pole switches, which are now, with the development of digital technology, used where it is necessary to open the positive and negative conductors and completely disconnect the electrical system from the voltage source. Single-pole rotary switches disconnect the car or boat battery from the load. They are used to open a positive or negative conductor.

Both types of mechanical disconnect switches are available with fire protection and IP66 protection, so they can be installed in open areas and on vehicles carrying dangerous goods, such as fuel tankers. Surely, such a device is installed on your yacht or boat, despite your readiness to implement new technologies. Keep these manual switches as a safety net, like the paper charts you keep in your chart table.

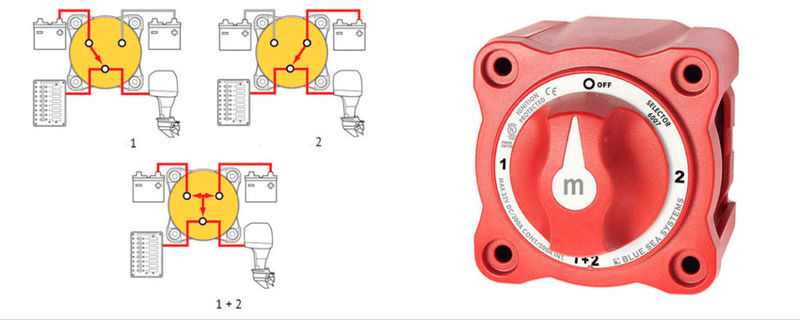

Then came the combination battery switches. If two batteries are installed on a boat, truck or car, one of which is used to start the engine and the second to power the equipment, then a four-position power switch is used.

This switch allows you to use the first or second batteries independently and, if necessary, combine them to start the engine. If the switch does not open the generator excitation circuit, then in order not to damage the diodes, turning it to the Off position is only allowed when the engine is turned off.

Batteries on boats and other types of water equipment are used for different purposes: to start a fuel engine, power an electric motor, echo sounders, navigation lights, radar, radio stations and other equipment. Moreover, to start the internal combustion engine you need a starter battery, and to constantly power the load - a traction battery. Sometimes there are universal batteries on sale - dual-use models designated DP or dual purpose Such a battery can cover the needs for supplying high starting currents for a gasoline or diesel engine, and for powering an electric motor and related equipment.

But in most cases, on yachts, boats and other motor vessels, several batteries are installed, and each of them performs its own tasks. And even to solve one problem, several energy storage devices can be used. For example, to power an electric motor and on-board equipment during long boat trips, when the energy stored by one battery is not enough, it becomes advisable to connect a second traction-type battery.

The second battery on a PVC boat or other watercraft can act as a backup power source or be used in parallel with the first, but for other purposes. It all depends on the equipment of a particular vessel and the energy needs of the equipment used. For example, it is advisable to use a starter battery only for starting an internal combustion engine and powering low-power devices during its operation, when the battery replenishes the expended energy from the generator.

It is recommended to connect the rest of the on-board equipment, electronics and portable equipment to a separate traction-type battery. A separate traction battery is also needed to power the electric motor. Although you can connect auxiliary equipment to it. The main thing is that the stored energy is sufficient to meet the needs of all connected loads. If the battery life with such connection of devices is insufficient, installing a second battery will help increase it. An additional power source reduces the load on the main battery and allows you to use it longer without allowing deep discharge.

On motor vessels, different methods are used to connect an additional battery. For example, on boats with an internal combustion engine it is often connected using an isolation relay. In this case, the two-pole switch creates 2 independent circuits - starting and service. When the internal combustion engine is running, the relay closes and both batteries are charged from the generator. When the fuel engine is turned off, the relay opens and the starting battery is isolated. During such periods, on-board devices receive energy from the service battery.

As a result, the starting battery is used only to start the internal combustion engine and is maintained in a fully charged state, which eliminates problems with starting the fuel engine and the on-board equipment does not overload the starting battery.

Typically, a service battery differs from a starting battery both in purpose and in the type of chemistry. Therefore, a DC-DC charger is used to charge it from the generator. It is connected to the positive terminals of both batteries and connected to a common negative bus. Such a charger not only uses the power of the generator, but also transforms its output voltage into a 4-stage charging profile. The main parameters of this profile - voltage and duration of each charging stage - are stored in the device’s memory after you specify the type of battery used once. Then the charge is replenished automatically, and the correctly selected charging algorithm extends the service life of energy storage devices.

It would seem that one could be dissatisfied with such a connection of the batteries available on the yacht through mechanical switches. But there are disadvantages, and there are many of them:

- the switch should be located fairly close to the batteries;

- the user must determine for himself in what position the switch should be set when the engine is stopped;

- when the switch is stopped in the “ALL” position, the batteries connected in parallel will be discharged simultaneously when powering other consumers during parking;

- risk of failure to start the engine due to deep discharge of the starting battery;

- batteries with galvanic coupling in the “ALL” position will discharge each other, and when external consumers are disconnected, the charging of these batteries will occur unevenly.

But even if you modify the motor circuitry with galvanic isolation, you will still have to monitor the switch positions before starting the main motor (or trolling motor, if you have one).

So, here's digital switches eliminate all these inconveniences, which, if ignored, can lead to dangerous consequences - short circuits, fire and electrical injuries. Programmed for critical values, digital switch will redistribute excess energy or turn off the power.

Digital switching replaces standard mechanical contacts, fuses, wiring harnesses and buses with electrical impulses carried over NMEA2000, CAN or Ethernet buses, and eliminates most mechanical switches on a control panel or dedicated circuit panel. With a simple interface via a stand-alone patch panel or multifunction display, you can monitor and control such systems.

Operating Principles of Digital Battery Switches

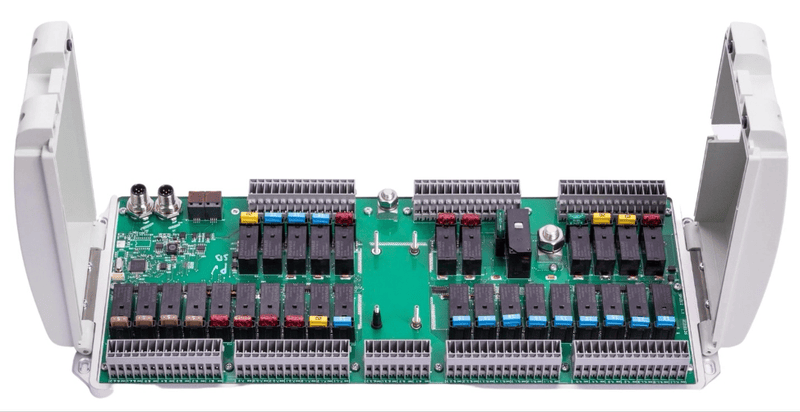

Digital switches are equipped with a DC power distribution unit. For example, such a block of Nereide 2 from Simarine has 30 outputs with a current rating of up to 10 A and one output with a current rating of up to 30 A. The maximum current for which the unit is designed is 200 A.

Both batteries and expansion modules are connected here, including a module that supports NMEA200 protocols. This allows you to switch all electrical equipment not only through the switching model of the monitoring system, but also directly from the multifunction chartplotter. This greatly simplifies the management of your yacht, including remotely. Further enhancing the possibilities is the compatibility of this digital switch with all SiCom modules.

Digital switches interact with on-board systems and sensors. Any error, such as a blown fuse, a stuck relay or lack of supply voltage, or a failed sensor, will be displayed on the control panel.

And most importantly, you can eliminate some of these errors even at a distance, which is facilitated by the already mentioned protocols and communication standards NMEA2000, CAN bus, as well as compatibility with SiCom modules. For example, redistribute power sources if one of them has reduced the usual readings.

Benefits of Using Digital Battery Switches

In addition to the advantages of digital battery switches, which we have already described above, I would like to especially note the reduction in wiring weight. After all, such systems have short cable runs, since the switching control panel can be installed at the equipment, and the shunts and modules used that work using NMEA2000 protocols will allow you to transfer measurements and other data directly to your multifunctional display installed on the control panel. Eliminate cable clutter and save valuable copper raw materials.

Increased Reliability and Safety

This is the most important advantage of digital battery switches, like all innovations that improve navigation safety and provide ship systems with additional reliability during operation.

Due to the precise calculation, programming and monitoring of the battery condition in several parameters, as well as through the prompt redistribution of energy, preventing rapid discharge or exceeding the charge level, the risk of short circuit and overheating, and therefore a fire on the ship, is significantly reduced. Agree, the human reaction cannot compare with the response of a well-tuned digital battery switch.

A yacht equipped with a digital battery switch will not suffer from problems due to incorrect connections. The system simply will not work if the connection does not meet the instructions or initial calibration.

Precision and Control

Digital switches are capable of controlling the supply of electricity from different suppliers (shore power, generator, solar battery, etc.) and its distribution to consumers in real time. That is, at any moment of the voyage you can find out all the data on the listed objects, including temperature. In addition, the alarm relay is always on guard, which will give an audible or visual signal if the critical values predetermined and entered into the monitoring program are violated in any direction.

In addition to precise control of the power supply, the owner of a yacht equipped with digital battery switches has the ability to remotely monitor and control the battery system and the power supplies connected to them, as well as the equipment that consumes this energy. To achieve this, most manufacturers of such systems have developed applications that can be used at a considerable distance from the yacht using a smartphone.

FAQ

How often should digital battery switches be calibrated?

Typically, calibration is performed only once during installation. But if the battery system changes in any way (batteries are added or removed), the calibration can be re-calibrated, changing the names of the various batteries.

Can digital battery switches automatically switch power sources on a yacht?

This is one of their most important functions, which ensures correct charging of all batteries on the yacht. The ability to switch energy sources for batteries also eliminates their critical level of discharge when any of these sources fails.

What energy management systems can integrate with digital battery switches?

Almost all manufacturers of digital battery switches are also manufacturers of energy management systems. Therefore, digital switches are most effectively combined with energy monitoring and energy management systems from the same manufacturer.

But knowing well the most advanced energy management systems that are presented in our marketplace, we can say that often digital switches from one manufacturer are perfectly compatible with systems from other manufacturers, as long as they meet the voltage, current and resistance input parameters, as well as input connectors. But in each individual case this compatibility should be checked separately.

Does electromagnetic interference affect the operation of digital battery switches and how can it be prevented?

Digital battery switch models have improved electromagnetic compatibility and are designed to operate normally when exposed to this interference. Since every yacht has radios, cables and power switches are the main sources of such interference.

How long do digital battery switches last and do they require special care?

It all depends on the user, correct installation and compliance with the operating rules, which are usually described in the instructions. If all these requirements are met, then digital switches can overcome the manufacturers' warranty period, which they usually set at 3 years.

Digital battery switches require the same care as any electrical equipment installed on a yacht. It should be protected from water, especially sea water, as electrochemical corrosion may occur. But, like any marine equipment that is installed in areas of the yacht protected from waves, they have a certain degree of water resistance, resistance to vibrations and rolls, since battery monitoring systems are usually complemented by inclinometers and tank level monitoring modules.