From this article you will learn what are marine watermakers for yachts, what is their design and basic principles of work. You will also learn how to accurately determine what kind of watermaker capacity is required specifically for your purposes. We will also talk about the advantages and disadvantages of marine watermakers.

Introduction

Definition of Marine Water Makers for Yachts

A seawater desalinator is a technical device that can be used to remove salts dissolved in seawater. The fresh water obtained after the purification procedure can be used not only for, let’s say, a washing machine, but also for cooking and drinking, since simultaneously with desalination, all types of contaminants and impurities, as well as bacteria and viruses, are removed from sea water.

Importance of Understanding How They Work

Sometimes the yacht just cannot do without a reliable watermaker on board.

If your yacht's route usually lies in coastal waters with frequent calls into ports and marinas, the need for a watermaker on board will not be acute enough.

But if your plan is to cross the Atlantic, you will need large supplies of fuel, food and water. All this takes up a lot of space and adds weight to the boat. It is possible to reduce the required volumes of fuel thanks to solar panels, food – by using canned products. To be honest, all this will have very little effect on the weight of the boat. But getting rid of full fresh water tanks makes the yacht a ton lighter, or even more, all thanks to the watermaker. Desalination equipment is also desirable if you are going to sail in places where fresh water is scarce or expensive.

In general, desalination equipment is usually used for long-distance crossings. If it breaks down, you cannot hope to quickly arrive at the port and call a service company to repair the watermaker. And not in every port, and even more so in the marina, you can find the right specialist. Therefore, the maintenance of the distiller will most likely be charged with the duties of one of the crew members. And we are not even talking about solo sailing, when the skipper has to be a master of all trades.

Even in coastal conditions, in case of charter voyages, it is better to have a watermaker on board and know how to operate and repair it if necessary.

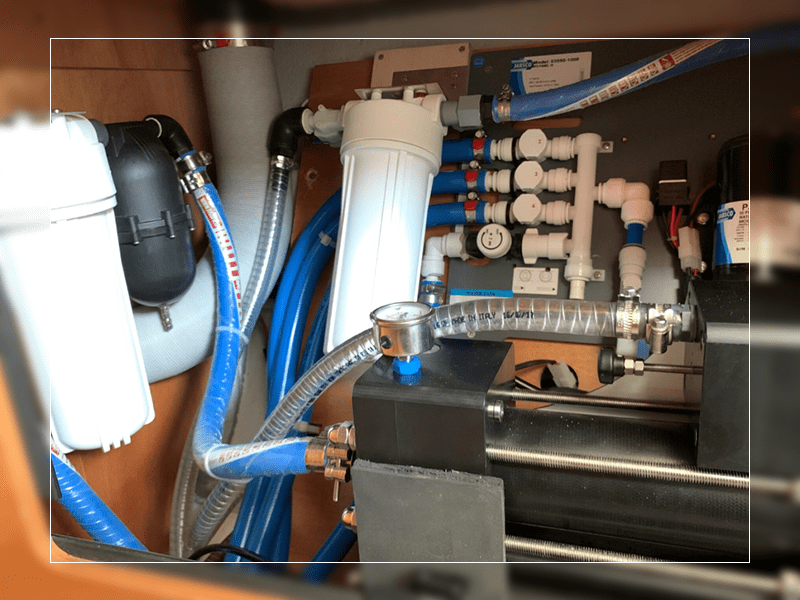

Components of a Marine Water Maker

Since the article deals with the desalination of sea water for the needs of a small fleet, let us dwell on the characteristics of desalination plants, the operation of which is based on the reverse osmosis process. All components of this system, as well as the distiller itself, must be made of materials that are not susceptible to corrosion: plastic, polymers, ceramics, stainless steel. Consider the main components of this most popular desalination equipment among yachtsmen.

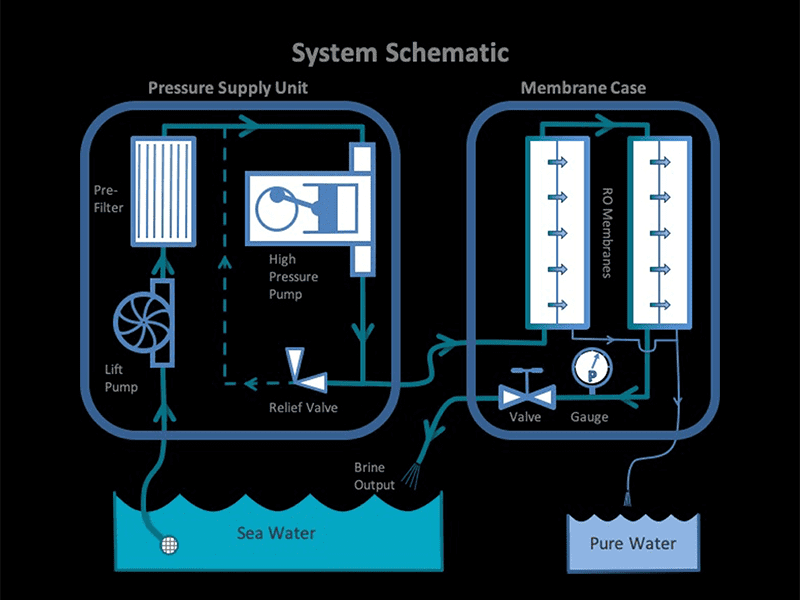

Intake System

Outboard water enters the desalination system through the inlet valve. The entrance to the intake system must be located below the waterline so as not to trap air.

Pre-filtration System

Pre-filtration is a coarse cleaning – thanks to mesh filters, large contaminants are removed before water enters the fine filters. The pre-treatment unit needs to be checked regularly, so it is better to install it in an easily accessible place, if the design of the water maker allows it.

High-Pressure Pump

With the help of a high-pressure pump, the pretreated high-pressure sea water is directed to the reverse osmosis membranes.

Reverse Osmosis Membrane

Through the microscopic holes of these semi-impermeable membranes, only pure water molecules are forced under high pressure. The number of membranes affects the performance of the desalter.

Post-treatment System

In order to improve the quality and purity of water, ultraviolet lamps, mineralization tablets and other techniques are used.

The Reverse Osmosis Process

Almost all models of the last decade marine water makers for yachts and boats operate on the principle of reverse osmosis.

Definition of Reverse Osmosis

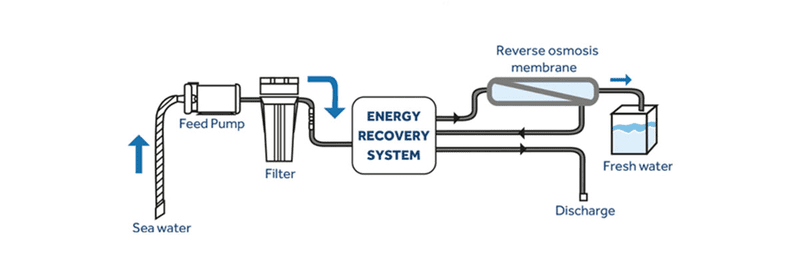

The reverse osmosis process for desalination consists of pumping sea water and forcing it through a very thin semi-permeable membrane using a high-pressure pump.

How Reverse Osmosis Works in Marine Water Makers

For yacht distillers, membranes are used that allow only pure water molecules to pass through. All other components of sea water remain in the brine, and these are the salts themselves, all types of pollution, as well as microorganisms, including harmful bacteria and microbes. Fresh water enters the storage tank, and the brine with all contents is dumped overboard.

Understanding Water Quality and Output

The whole point of this device is just getting fresh water onboard, but quality and amount of it are not set in stone.

Factors That Affect Water Quality

The quality of purified sea water is directly dependent on the performance of the desalination plant. A decrease in the declared performance is a sign of a malfunction of the equipment, which does not guarantee the quality of the water at the outlet, which is promised by the manufacturer of the desalination plant.

In many ways, the quality of desalinated water also depends on the place of its intake; it is better to do this on the high seas and not in ports or marinas.

We recommend that you regularly check the quality of treated water using a TDS (total dissolved solids) meter if it is not built into your distiller.

Water Output Measurement

The right choice of a desalinator, depending on its performance, is literally a matter of health and even life of passengers and crew. If marine water maker will not be productive enough, then the discomfort from not being able to take a shower is the least that a lack of fresh water can lead to. More severe consequence is body dehydration – loss of over 10% of total body water already leads to physical issues, death occurs at a loss of between 15-25%.

If the capacity of the watermaker produces an excess of fresh water, there is a danger that the desalination equipment will stay idle for some time. Since the membranes will not be constantly washed during the shutdown of the desalter, they can become overgrown with salts and mold, which will provoke the growth of bacteria.

Based on practical experience, the maritime community has determined that when calculating the need for clean drinking water, one should proceed from a norm of 30-40 liters per person per day. Multiply this figure by the number of people on board, add here the expense for technical needs and a dozen liters for insurance - this will be the performance of your future distiller.

Maintenance and Care for Marine Water Makers

Like any yacht equipment, seawater desalters require regular preventive inspection in order to timely troubleshoot.

Regular Maintenance Requirements

It has already been mentioned above that the idle time of the distiller without special treatment (preservation for storage) is dangerous due to the overgrowth of membranes and the development of microorganisms on them. Therefore, this equipment requires special and regular maintenance.

The main type of maintenance work is rinsing the membranes with clean, chlorine-free water. The latest generation of desalters have an automatic membrane flushing system, but this process can also be performed manually. It is necessary when the distiller is idle for more than 1-2 days (a shorter period - when sailing in tropical regions) or when the equipment performance decreases. So just check the quality and quantity of fresh water produced regularly.

Common Issues and Troubleshooting Tips

The performance of the watermaker may also be reduced for other reasons, for example, the weakening of rubber rings, fittings and other connecting parts. In this case, they will need to be replaced.

If you know you won't need the desalter for some time, you should treat it with a biocide in addition to flushing the membranes to prevent deposits and mold from forming. The same process should be carried out from time to time even with the device constantly running for preventive purposes.

On a yacht with a watermaker, it is recommended to have a biocide and a repair kit with spare filters, membranes, rings and fittings.

[vitrina]1631,1855,1824,1828,1821[/vitrina]

Advantages and Disadvantages of Marine Water Makers

Like any marine equipment, seawater makers have their pros and cons, which should be considered when purchasing.

Advantages

If a sea water maker is installed on board your yacht, you will receive the following benefits:

- fully automated desalination process with minimal maintenance;

- high level of sea water purification - from 97 to 99%;

- additional comfort of life on board;

- unlimited range of sea crossings;

- safe water supply onboard in regions where water quality does not pass the necessary sanitary control;

- emergency water supply in case of tanks breakage or water spoilage inside;

- reducing the weight of the yacht, increasing its performance by eliminating the need for constant storage of large volumes of water;

- cost savings in some Caribbean ports where water is scarce and therefore expensive.

Disadvantages

After seeing many different types of watermakers in action, the topRik team revealed only two drawbacks. The first is that not all yachts can be equipped with a stand-alone watermaker, as it takes up a lot of space. But there is good news in this regard: the experts of our marketplace will select a modular model for your yacht, which is not inferior in performance and quality to an autonomous one.

Another factor that is usually considered a disadvantage is the cost of marine water makers. But the many years of practical experience of the topRik team shows that it pays for itself in the long run, so it is always possible find an option for the customer interested in this device.

The practice of sea voyages and chartering clearly confirms that a watermaker on board a yacht is the key to a comfortable and safe cruise with family, friends or charter passengers – consider getting one for your own boat!