topRik experts present another module that is used to expand the capabilities of the Simarine PICO system monitor. In previous articles we remind you that we have already introduced you to this system, which monitors the operation of batteries, visually displaying information about their condition, as well as (depending on the version) monitors and shows the level of liquids in the yacht’s tanks.

In order to expand the ability to monitor the condition of tanks, an additional universal tank Level module ST107 module was created. This module is included in the Pico Blue and Pico Standard versions.

The ST107 liquid level and voltage control module can be used to measure temperature or connect resistance sensors to measure liquid levels in any tanks that contain fuel, fresh water, potable water, sea water or waste water. You can connect any sensor for determining the liquid level in the tank, if this sensor operates within the range specified for various versions of the Pico system, but more on that later.

Outstanding feature of Tank Level module ST107 is a built-in programmable alarm relay. It can be configured to output a 1A signal when an alarm is triggered. The alarm is triggered when:

- wastewater tank overflow;

- reducing the fuel level in the fuel tank to a certain value;

- reaching the minimum, specially programmed level of drinking water.

It seems that not only experienced yachtsmen, but also novice sailors are aware of the importance of monitoring the level of various liquids on the ship.

Overfilling the tanks threatens flooding, possible short circuits in the electrical system, and if we are talking about wastewater, then pollution and odors, which will have to be difficult and long to deal with.

Let’s not even talk about the dangers of a lack of fresh water in case of untimely replenishment of its reserves – just remember that dehydration is not just discomfort, but a risk to human health and even life.

A critical decrease in fuel level will simply damage the engine.

To eliminate these risks, you should simply expand monitoring of the condition of all tanks with various liquids. Tank level module ST107 is your impeccable and efficient assistant, which does an excellent job of enhancing safety and ensuring the comfort of the ship’s crew and passengers.

Main Characteristics

Like any electrical equipment for yachts, tank level module ST107 has standard and unique characteristics. Their knowledge will help you create the most informative tank level monitoring system. Therefore, you will have to compare the performance of this unique module with the capabilities and characteristics of your equipment, for example, check the compatibility of the type of sensors used, the capabilities of your power supplies on the yacht, etc.

Supported Tank Types

Tank level module ST107 supports types of tanks of various configurations and purposes: for fuel, drinking and fresh water, sea water, waste water.

To store drinking water, tanks made of food-grade polyethylene or polyvinyl chloride are used, for waste gray and black water - from metallocene and other types of polyethylene.

Tanks are either hard or soft (elastic). The latter are used even in limited space, when there is not enough space on a yacht or boat for rigid tanks.

Expansion tanks and complete tanks made of various materials can also be included in the monitoring system from Simarine.

To use not only cold but also hot water on board, boilers are installed. It also needs to control not only the liquid level, but also the water temperature.

Sewerage installation is not a matter of comfort, but of basic necessity. To drain gray water, special fecal canisters are used, the level of which requires mandatory monitoring in the limited space of the yacht.

Fixed tanks are part of a yacht's fuel system and monitoring their fuel levels is vital to the ship's crew. Regardless of material, fuel tanks are also supported by the ST107 module.

Level Measuring Range

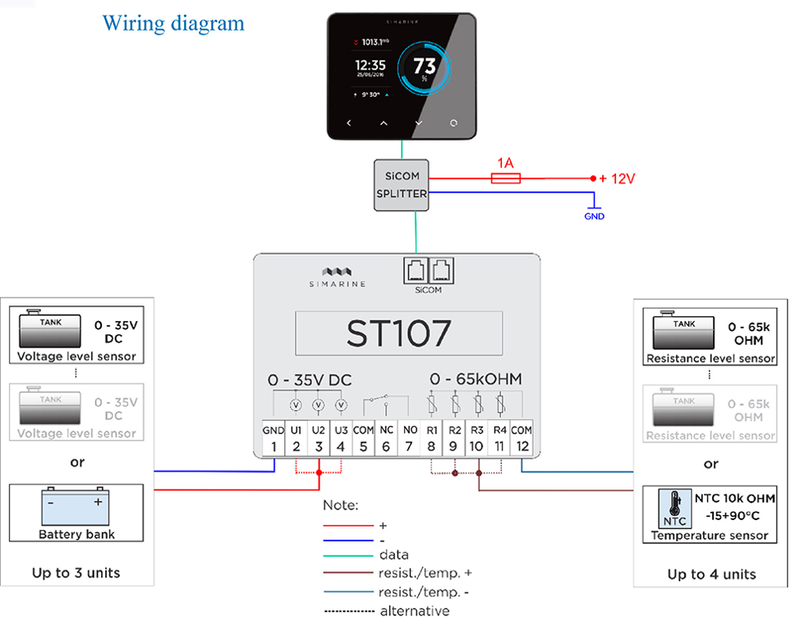

So, what kind of expansion of the monitoring system will get with the ST107 module? And let's not forget about the additional alarm relay! By connecting the ST107 module to the Simarine PICO system monitor you receive additionally:

- resistance inputs – 4 connectors;

- voltage inputs – 3 connectors;

- alarm relay – 1.

For these inputs you will need sensors operating in the following ranges:

- for resistance inputs – sensors in the range from 0 Ohms to 65,000 Ohms;

- for voltage inputs – sensors in the range from 0 V to 75 V.

Below we will complement the characteristics of tank level sensors in terms of their type compatibility.

Types of Sensors That ST107 Is Compatible With

A sensor is a device that converts the input effect of any physical quantity into a signal convenient for further use.

The ST107's resistance inputs are compatible with analog tank level or resistive temperature sensors, and the voltage inputs are compatible with analog tank level and custom sensors.

The fairly wide ranges that we discussed above allow the use of almost any sensor from the listed types.

To help you evaluate your current sensors, check out the varieties of resistive and analog voltage sensors that can be used to detect liquid level and temperature.

Resistive Level Sensors

The principle of operation of resistive or ohmic sensors is based on a change in their active resistance when the length, cross-sectional area or resistivity changes.

In addition, the dependence of the active resistance value on the contact pressure and illumination of the photocells is used. In accordance with this, resistive sensors are divided into groups:

- contact;

- potentiometric (rheostat);

- strain gauge;

- thermistor;

- photoresistor.

Contact sensors are the simplest type of resistor sensors that convert the movement of a primary element into an abrupt change in the resistance of an electrical circuit. Contact sensors are used to measure and control forces, movements, temperatures, sizes of objects, control their shape, etc. Contact sensors include:

- travel and limit switches;

- contact thermometers;

- electrode sensors used primarily to measure extreme levels of electrically conductive liquids.

The disadvantage of contact sensors is the difficulty of continuous monitoring and the limited service life of the contact system. But due to the extreme simplicity of these sensors, they are widely used in automation systems.

Rheostat sensors are a resistor with varying active resistance. The input value of the sensor is the movement of the contact, and the output value is the change in its resistance. The moving contact is mechanically connected to the object whose movement (angular or linear) needs to be converted.

The most widely used is a potentiometric circuit for connecting a rheostatic sensor, in which the rheostat is connected according to a voltage divider circuit. A voltage divider is an electrical device for dividing direct or alternating voltage into parts.

A voltage divider allows you to remove (use) only part of the available voltage through elements of an electrical circuit consisting of resistors, capacitors or inductors. A variable resistor connected according to a voltage divider circuit is called a potentiometer.

Typically, rheostatic sensors are used in mechanical measuring instruments to convert their readings into electrical quantities (current or voltage), for example, in float liquid level meters and various pressure gauges.

Strain gauges are used to measure mechanical stress, small deformations and vibration. The action of strain gauges is based on the strain effect , which consists in changing the active resistance of conductor and semiconductor materials under the influence of forces applied to them.

Thermometric sensors are used as temperature sensors and are often called "resistance thermometers", as well as sensors for flow rate, thermal conductivity of the environment, density of gases, etc.

In sensors of this kind, a two-stage conversion occurs: the measured value is first converted into a change in the temperature of the thermistor, which is then converted into a change in resistance.

Level Sensors with Analogue Output

They measure the water level in the tank, as well as other liquid and solid media. Their main types:

- Non-contact ultrasonic. They do not interact directly with the measured medium. They are distinguished by high accuracy and speed of measurement even over long distances.

- Capacitive. Allows measurements to be taken continuously or at fixed points. Optimal when stability of measurements in difficult conditions is more important, for example, at high/low temperatures, the presence of dust.

An analog water or fuel level sensor is selected taking into account process parameters: operating temperature, pressure, and others. Also, when choosing, take into account the physicochemical properties of the liquid itself.

If your level sensors meet the above specifications, they will be compatible with the ST107 module.

Temperature Sensors

But in addition to monitoring the level of liquids in the tank level module ST107 also supports temperature monitoring. All supported temperature sensors are resistive type, which means you will need one resistance input for each temperature sensor.

Simarine PICO system monitor is compatible with the following sensors that read the following temperature levels:

- down to –13°C – NTC 10k;

- down to –20°C – NTC 5k;

- down to –40°C – NTC 1k.

Nutrition and Energy Consumption

Tank level module ST 107, like all Simarine PICO system monitor is powered by the yacht's onboard electrical system. Voltage – 6-35 V DC.

Voltage – 6-35 V DC. You can connect shunts to either the LOW (-) or HIGH side (+), if the system voltage does not exceed 35 V. If it is exceeded, connecting a shunt to the LOW (-) side is mandatory.

You can also wire shunts, connecting some to the positive and some to the negative terminal, or even to the same module.

Dimensions and Materials of the Case

Since the ST107 module is installed in an area that is not flooded, the device does not have full marine protection. However, it is made of materials that do not corrode. Water ingress is excluded - this is a standard requirement for the safe operation of any electrical device.

The photo below shows how compact this module is, so it will be easy to find a dry place for it that is not prone to getting wet.

Installation and Configuration

Simarine electronics must be carried out by qualified electricians using appropriate safety equipment. Follow safety regulations when working with batteries and use protective clothing and eye protection when working with them.

If you do not have electrical experience and the appropriate permits, you should hire a professional to install and then configure the Simarine PICO system monitor. The installer must follow the instructions provided by the manufacturer - they are included in the delivery package.

It is better to mount the display on the control panel so that it is easy to see. Tank level module ST 107 can be installed remotely, then compatible sensors are connected to it according to the diagram and an alarm is connected to it if you select this option.

Functionality

Tank level module ST107 included with one of the Simarine PICO system monitor versions can be called programmable logic controller (PLC) for automation, data acquisition system, remote I/O. PLC is a microprocessor device for collecting, converting, processing, storing information and generating control commands. It has a finite number of inputs and outputs, sensors, keys, actuators connected to them to the control object, and is designed to operate in real time.

All produced level sensors are divided according to functionality into level meters and alarms.

Level transmitters provide continuous level measurement in real time. Their design includes a measuring part with sensors. Data from the measuring part is processed by an analog or digital electronic circuit included in the sensor.

Alarms are sensors designed to determine a given level; they signal when the level has reached a predetermined value. The alarm is triggered when the sensing element is blocked or released by liquid.

As you can see, tank level module ST107 meets all the characteristics of a PLC, so it is multifunctional. It not only monitors the level of various liquids in tanks of various shapes, but also controls it using a special relay.

The built-in programmable alarm relay will warn you not only when the level of fuel or drinking water is critically low, not only when the sewage level is exceeded, but also when the battery charge level drops below 30%.

That is, module ST107 provides the monitoring system with both the functions of a level gauge and the functions of a signaling device.

In addition, the module monitors the temperature in the tanks and also “helps” control the operation of batteries, including solar panels.

Advantages and Disadvantages

Like any marine equipment included in the ship's electrical system, as well as performing measuring, monitoring and signaling functions, tank level module ST107 has both advantages and disadvantages.

Advantages of ST107

- Supports all types of ship tanks.

- Compatible with several types of level and temperature sensors.

- High measurement accuracy.

- Multifunctionality: monitoring tank levels, temperatures, batteries.

- Easy to install and use.

- Compatible with remote monitoring application.

- Reliability and durability.

Disadvantages of ST107

- Restrictions on compatibility with some types of sensors.

- Possible difficulties in setting up for users without technical experience.

In fairness, it should be said that these shortcomings are a continuation of the advantages of the module, since it prefers innovative sensors and prevents accidents with inexperienced installers.

Technical Support and Service

Manufacturer of tank level module ST107, Simarine, is constantly improving its monitoring devices. For example, an application for remote monitoring, including tank levels, was recently developed. The firmware allows you to monitor the condition of the tanks and batteries of your yacht, which is parked at the pier, during your walk around the city using a smartphone.

For all Simarine PICO system monitor products, including the shunts and modules included in the design, you get three years warranty from the date of purchase. If module If the ST 107 refuses to work correctly within this period, it will be repaired or replaced free of charge.

Exceptions are the case if the defect arose as a result of user intervention in its design, installation, operation or configuration without the written consent of the manufacturer, or other violations of the installation and operating instructions. Failure to promptly notify the manufacturer of a defect may also result in denial of warranty service.

The topRik marketplace offers a complete set of displays, shunts, modules and applications for all versions of Simarine PICO system monitor. If you have any questions when choosing Simarine PICO shunts and modules, ask them to the topRik marketplace experts by phone, through the site’s contact form, or send them to our email address [email protected].