A charger is a device that allows you to recharge batteries and accumulators with energy from an external network. It includes a voltage converter, rectifier, stabilizer, control board and charge indicator. The performance and durability of the used power elements depend on the correct choice of a charger for batteries, its reliability and functionality.

Using a reliable charger that is designed for the specific battery type and has the correct specifications helps to:

- maintain batteries in working condition;

- preserve their cyclic resource;

- optimize charging time;

- fully charge them without overheating, overcurrent, exceeding the upper voltage limit and other risks;

- avoid wasting time monitoring the charge level - thanks to the automatic termination of the process when the battery capacity is fully replenished.

Chargers are primarily classified by the type of batteries they are designed for. For example, the topRik marketplace sells models for marine Li-ion batteries of all modifications, as well as LiFePO4.

Depending on how many elements are connected in the battery in a parallel-series circuit, a charger with the appropriate voltage and charging current values is required to charge it. According to the operating principle, chargers can be pulse, analog, digital, automatic and smart.

Let's remember the features of boat batteries of various types and modifications.

Three types of lead-acid batteries are used as traction batteries for electric boat motors, which differ in price, service life and technical characteristics.

Liquid Electrolyte Traction Batteries

The most common type of lead-acid batteries for electric boat motors. They are produced with a capacity of 70 to 120 Ah, industrial batteries with a capacity of 140 Ah.

Liquid electrolyte batteries require periodic testing and topping up with distilled water, and maintenance-free marine models allow this. Due to the fact that free hydrogen release is possible in liquid-acid traction batteries, they tolerate overcharging better than gel and AGM batteries, but they discharge by 6-7 percent per month.

Liquid-acid batteries are installed only in a vertical position; they do not tolerate strong vibrations and tilting, as there is a risk of electrolyte spillage.

AGM Battery For Boat with Electric Motor

Sealed batteries with adjustable valves and layers of thin, highly porous glass fiber separator impregnated with electrolyte and tightly compressed between the positive and negative plates of the battery. The separator ensures uniform density of electrolyte over the entire surface of the plate, reinforces it and makes it resistant to shock and vibration.

The internal resistance of AGM traction batteries is lower, which means greater starting power and charging speed. They can be charged with current up to 40 percent of their capacity and reused with an electric motor on a boat faster than other types of traction batteries.

Service life of up to 10 years, self-discharge of 3% per month and the ability to restore the original capacity in 1-3 hours make AGM batteries indispensable for those going fishing with an electric motor for several days.

These are maintenance-free models, there are no leaks or electrolyte spills, and they can be installed on their side.

A charger with adjustable charging voltage is required.

Boat Batteries for Electric Motors with Gel Electrolyte

Traction batteries with gel electrolyte have advantages over conventional liquid-acid batteries - their self-discharge is 1-3% per month, they are sealed, withstand the greatest number of charging cycles and do not require maintenance.

Valves built into the hull maintain the internal pressure at an excess level, but open and equalize it if necessary. The design of the batteries eliminates gas emission and electrolyte spillage, so they are safe to install near boat electronics. This type of battery lasts longer at elevated ambient temperatures and can withstand up to 2000 discharge cycles.

The traction gel battery is suitable for starting a boat motor with a capacity of up to 40 HP, connecting a 36, 24 or 12-volt electric motor, a winch, a pump or an echo sounder. The correct choice of charger is important for it - overcharging leads to a decrease in capacity and puts the battery out of order.

Maintenance-free, no leaks or spills of electrolyte. Durable and vibration-resistant. Can be installed on its side, safe for use on boats and yachts.

A charger with adjustable charging voltage is required.

Yacht Lithium-Ion Batteries

Lithium batteries have undeniable advantages over lead-acid batteries. Incomplete charging or deep discharge do not harm such a battery.

With the same nominal capacity, a lithium battery provides twice as much useful electrical energy as a lead-acid battery. It is much lighter, does not emit explosive gases and, if handled correctly, lasts many times longer.

A lithium battery absorbs all the available current until almost the very end of charging, so it can be charged much faster than a lead-acid battery.

Ah received during charging, they return 0.997 Ah during discharge. Very little charge is lost, so lithium batteries do not need a long absorption stage.

Lithium batteries have low self-discharge and higher and more stable voltage during discharge . The fastest way to charge a lithium battery is with a combination charger and inverter.

Main Parameters of the Charger

The main characteristics when choosing the right charger for a boat battery are (among other parameters) voltage and current.

Let's consider how the voltage of the charger and the charging current affect the speed and safety of charging different types of marine batteries.

While using a higher charging current may seem like a way to speed up the process of replenishing the battery's energy, this approach carries risks and potentially negative consequences for both the battery itself and the overall safety of use. In this context, it is essential to understand the specific changes and problems that can occur when charging a battery with a higher current, as well as the long-term effects of this approach on the performance and life of batteries.

Using the recommended charging current ensures the efficiency and safety of the process. Current exceeding the optimal values can cause overheating, accelerated wear of the battery and even damage it.

The battery temperature during charging should be monitored, as too high a temperature can lead to accelerated aging and degradation of the battery. Many chargers include temperature control features to prevent overheating, such models are widely represented in the topRik marketplace.

For more information on the consequences of choosing the wrong charger based on current and voltage ratings, see below, in the section “Dangers of Using Incompatible Chargers”.

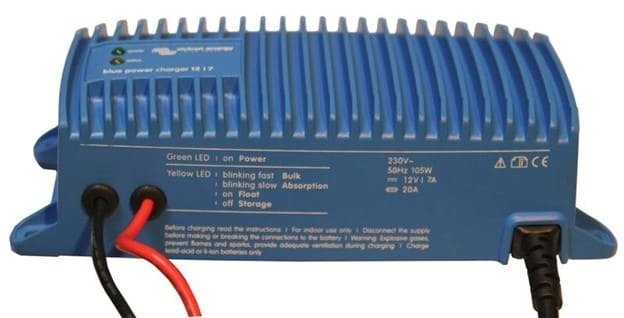

Protection Class

Since we are talking about equipment intended for use in marine conditions, attention should be paid to the protection level of marine battery chargers.

Waterproof chargers are available in several protection classes.

- IP65 charger – dustproof with protection against water jets from any direction. The cases are usually made of plastic. They are designed to work in an environment with humidity up to 95%. They have built-in protection against incorrectly connected polarity, short circuit and overheating. Powerful devices have a cooling fan with a lower protection class. They work at an ambient temperature from -30 to 30 C. Charging current up to 120 amperes, voltage 12 or 24 volts.

- The IP67 charger is dustproof and can be immersed in water for a short time to a depth of one meter. It is not intended to work in water. The cases are made of aluminum or shockproof plastic. They work at temperatures from -20 to 40 degrees. The charging current is up to 25 amperes. They work without a fan, cooling by a radiator on the case.

- IP68 charger – dustproof, works when submerged in water. Shockproof case is made of aluminum or aluminum with plastic inserts. Charging current up to 20 amperes. Works without a cooling fan.

Multi-Stage Charging

The process of charging batteries involves passing an electrical current from an external source through the battery, causing chemical reactions within the battery and storing energy. This process is governed by certain physical and chemical principles, and doing it correctly is critical to maintaining the health of the battery and maximizing its life.

Different types of batteries, such as lead-acid, lithium-ion and nickel-metal hydride, have unique chemical compositions and require different charging regimes. This includes specific charger voltages and currents that are optimal for each type.

Most modern batteries charge in stages, including a low-current precharge, a bulk charge, and a final or float charge. These stages help optimize the charging process by preventing overheating and overcharging.

Bulk charging. During this initial stage, the battery is rapidly charged to approximately 80-90% of its capacity. The charger supplies a significant current to replenish the energy expended by the battery in previous discharges.

Accumulative charging. After the battery reaches 80-90% charge, the current is reduced, but the voltage is maintained constant so that the battery gradually absorbs the remaining energy. This prevents overcharging and helps to increase the battery life.

Maintenance charging. Once fully charged, the system switches to a lower voltage to maintain the battery at full charge without damaging it. This stage is critical to maintaining the battery's readiness for use and extending its life.

How to Choose a Lead Acid Battery Charger

A modern charger has an algorithm for each type of traction lead-acid batteries. It should be known that lead-acid batteries require maintenance charging on the boat between uses. Liquid electrolyte batteries are charged at 14.8 V and then desulfated at 15.1-15.5 V.

When properly charged and maintained, deep cycle liquid acid batteries can withstand hundreds to thousands of charge cycles and can be used with an electric boat motor for 5-7 years.

How to Choose a Charger for AGM and Gel Batteries

If you have a gel or AGM battery, you need to select a charger taking into account the presence of a charge profile for maintenance-free batteries. Why is this so important? Because in a serviced battery, in the final stage of charging - mixing the electrolyte - the permissible voltage per cell can reach 2.60 V, and in a maintenance-free battery - the maximum is about 2.35 V per cell. The voltage should not exceed this value due to the fact that the main part of the current from the charger will no longer go to charging the electrodes, but to electrolysis of distilled water in the electrolyte, but since maintenance-free batteries do not have the ability to add it, the battery will quickly lose water in the element (dry out) and will fail very quickly. An incorrectly selected charging unit for charging gel batteries reduces their service life by 7-10 times.

How to Choose a Lithium-Ion Battery Charger

A charger for Li-ion batteries is a source of stable voltage that supplies a charging current of 0.5C–1C (50–100% of the battery capacity). Initially, recharging occurs with a constant charging current, and when the voltage reaches the upper limit, the charging current asymptotically approaches zero. This method is designated CC-CV: at the 1st stage, charging occurs with a constant current and most of the accumulated capacity is replenished, and at the 2nd stage, with a constant voltage, the remaining percentage of capacity is reached.

The maximum voltage for Li-ion batteries is 4.2 V per element. This is the voltage of fully charged power cells. For a battery, the upper voltage limit depends on the number of cells connected in series. For example, for a battery of 3 Li-ion batteries connected in series, the charging process should stop at 12.6 V. This is exactly the charging voltage of a suitable charger.

In the question of which charger to choose for a lithium-ion battery, there are 2 main conditions:

- a special charger is needed for Li-ion models - so that the permissible voltage does not exceed 4.2 V per element with a tolerance of 0.05 or 0.1 V;

- its parameters must correspond to the characteristics of a specific battery.

It is best to use a "smart" automatic charger that produces a charging current of 0.5C-1C and ensures the correct charging mode using the CC-CV method. Such devices have a built-in charging monitoring system and automatically turn off when the upper limit of 4.2 V per cell is reached. They do not allow the battery to be overcharged, prematurely "aged", lose capacity and fail.

LiFePO4 Battery Charger

LiFePO4 batteries differ from other types of Li-ion power elements by their chemical structure and operating voltage range. When fully charged, their voltage is 3.65 V per element. Otherwise, charging occurs similarly, using the CC-CV method, in 2 stages: with constant current - up to a voltage of 3.65 V per element, and then at a constant voltage with a charging current asymptotically approaching zero.

This means that a LiFePO4 battery requires a charger that:

- designed for batteries with this type of chemistry, so that during charging they do not go beyond the 3.65 V limit per cell;

- the output voltage corresponds to the assembly diagram and battery voltage;

- in terms of charging current – corresponding to the battery capacity, in the range of 1C–5C, although for fast charging of LFP batteries, currents up to 10C are permissible.

Lithium iron phosphate batteries have a stable chemical structure and can withstand high current loads without heating. Therefore, more powerful chargers are suitable for them, allowing you to significantly speed up the charging process. But you should not exceed the currents recommended by the manufacturer, so as not to accelerate the wear of the battery.

The Dangers of Using Incompatible Chargers

Incompatibility of the charger with the type of battery can cause various malfunctions in its operation, including failure.

Potential Problems

Particularly dangerous are violations related to the correspondence of the current and voltage of the charger and the battery.

Charging a battery with high current can have significant consequences that affect its performance, safety and lifespan:

- High charging current causes high rates of chemical reactions inside the battery, causing it to overheat. This can lead to damage to the internal structure, poor performance, and even thermal runaway, especially in lithium-ion batteries.

- Accelerated wear. Charging the battery with a high current accelerates its wear, reducing its overall service life. This occurs due to the more intense decomposition of the electrolyte and other components of the battery under the influence of high temperatures and accelerated reactions.

- Capacity loss. Constant charging with high current can cause the battery to "leak" capacity, i.e., reduce its ability to hold a charge. This is due to damage to the active material of the electrodes and loss of efficiency of chemical processes.

- Risk of swelling or explosion. In lithium-ion batteries, excessive current can cause internal damage and gas buildup, causing the case to bulge. In extreme cases, this can cause the battery to explode due to the rapid release of energy.

- Irreversible chemical changes. High charging current can cause irreversible changes in the chemical composition of the battery, reducing the number of charge-discharge cycles the battery can withstand before its performance deteriorates significantly.

As for overcharging, we are talking about exceeding the level of charging voltage recommended by the manufacturer. The danger of this situation is as follows: simultaneously with the increase in the battery charge level above 75-80%, the process of water decomposition into two components begins - oxygen and hydrogen. Moreover, this process is directly proportional, that is, the faster the charging voltage at the battery terminals increases, the higher the decomposition rate will be. As a result, there is an accelerated loss of water, and the positive current leads of the battery (grids) are subject to corrosion.

In addition, during recharging, as a result of electrochemical reactions, natural heating occurs inside the batteries, which can provoke "boiling" of the electrolyte with abundant gas emission. The release valves of sealed batteries are not always able to "etch out" the excess pressure created inside for a number of reasons, and it is transmitted to the battery case. When this process is controlled, charging occurs at the set values of voltage and charging current, natural heating of the batteries does not create problems. The main thing is to prevent the temperature from exceeding 50° C.

Another negative phenomenon that entails the phenomenon of battery overcharging is the rapid decrease in the electrolyte level in flooded batteries, where liquid electrolyte is used, but this is not related to the characteristics of chargers, so we will not dwell on this aspect here.

Using batteries with a charging voltage level below 13.5 V for 12-volt batteries is also dangerous, since this causes the phenomenon of progressive undercharging, i.e., insufficient replenishment of capacity after discharge. As a result, the state of charge of the power source decreases proportionally to the time of its use in this mode. Long-term use of batteries with a reduced charge always leads to the coating of the electrodes with an oxide film, which further reduces the efficiency of subsequent charges. This can also lead to sulfation of the plates, destruction of the electrodes and overheating.

In practice, many users set a low charging current when charging, especially old batteries. The batteries will, of course, charge, but the charging time will be unreasonably long (maybe up to several weeks), which many do not take into account. As a result, the battery will be in a discharged state for the entire charging period, which is almost equivalent to storing it in a discharged state, and this again leads to sulfation and accelerated aging of the batteries.

How to Avoid Shortening Battery Life Due to Choosing the Wrong Charger

To avoid the above-mentioned consequences from improper use or selection of a charger, you should carefully study the manufacturer's instructions. Chargers presented in the topRik marketplace are necessarily equipped with such instructions, which indicate the parameters of the charger and the types of batteries it is suitable for.

How to Check If Your Charger Is Compatible with Your Battery

To make sure that the charger is suitable for your battery, you should compare the characteristics that manufacturers indicate in the relevant instructions. As a rule, the instructions for different types of chargers indicate the parameters of the batteries they are suitable for.

You can also contact topRik experts who will advise you on the appropriate charger based on the type of your battery.

Tips for Choosing Universal Chargers

There are several types of chargers that can be used to restore modern batteries. Some of the most effective and easy to use are smart or universal chargers.

In this case, the definition of "smart" means that the device can not only restore the charge, but also automatically select the optimal operating parameters for a specific power source, as well as perform battery diagnostics, determine the initial charge value, etc. A built-in microprocessor controls all operating processes of such devices.

The popularity of intelligent microprocessor chargers is that they do not require a person to have special knowledge of the principle and cycles of battery recovery, time measurements and continuous monitoring of voltage reduction and changes in the charging current level.

The main feature of these devices is that the user only needs to know the capacity of the battery being charged. Pulse chargers have a similar operating principle, but they cannot monitor the battery condition and evaluate it. That is why smart devices are considered the most convenient and effective.

If we take a standard pulse device, the charging process will be as follows: first, the battery is charged to the nominal level, then the discharge stage is activated. A full charge may take up to two days. It is important to remember that the device must be controlled so that it does not exceed the charging current, and the electrolyte level in the battery does not decrease. With a smart charger, it’s all much more simple.

Smart chargers work on a completely different principle. An example of such a smart device is the Phoenix MultiPlus inverter-charger from Victron Energy, which is presented in the marketplace. It combines a combined inverter and charger in one housing. Its many features include a sine wave inverter, adaptive charging, PowerAssist hybrid technology and a variety of system integration features.