topRik team shares own experiences of using of mooring lines and accessories that facilitate the mooring of the yacht and ensure the reliability of securing your vessel on the pier, near piles, in an unequipped lagoon, etc.

The assortment of our marketplace allows you to choose mooring lines made from the most modern materials. A wide selection of parameters in terms of diameter, breaking load, design and type of weaving makes it possible to satisfy the requirements for moorings in exact accordance with the characteristics of your yacht. Just go to the section “Mooring Lines, Rope & Accessories” - and make your choice. But first, read the advice of our experienced sailors to make the right choice and then properly care for your mooring lines that you purchased in our marketplace.

topRik experts will also recommend tools, the first of which helps to quickly and effectively clean mooring ropes, and the second of which helps you quickly remove mooring lines without much effort. In the first case, you significantly extend the life of your mooring ropes and make it easier to care for them; in the second, you get rid of back pain and bottom dirt on the deck.

What Is a Mooring Rope and What Are Its Functions?

It doesn't matter if your yacht was launched last week or twenty years ago, no boat can do without running rigging on board. Different ends are responsible for controlling the sails and for safety when moored. The latter are the mooring cables that will be discussed.

The mooring end, or simply the mooring line, is a special cable. By means of it, the vessel is attached to a pier, barrels, beams, or other vessel, ensuring a stationary position of the vessel relative to the mooring object.

In practice, the mooring end is attached to the bollards of ship mooring devices or to the mooring cleat of yachts and other small fleet vessels. The other end of the mooring cable is usually equipped with a loop for fastening to shore bollards.

For some reason, some inexperienced yachtsmen decide to save money on mooring ropes. Moreover, ropes made from cheap polyester cost almost half as much as similar products made from high-strength fibers. At the same time, externally cheap cables look the same as expensive ones and even seem more elastic to the touch.

However, modern materials can mislead even more experienced yachtsmen, who, having decided to get serious about outfitting their boat, are often lost in the abundance of offers and options. Here, unfortunately, you cannot be guided only by the information provided by the manufacturers: many cables, especially the cheapest ones, are often positioned as suitable for all occasions.

On the other hand, spending half the onboard budget on the most expensive cables is also not very wise. When making a choice, you first need to think about the purpose of the purchase. The more accurately you know the scope of application of the cable, the easier it will be to choose the appropriate option. Its material and structure are of particular importance. Not only the price, but also the mechanical tensile properties, critical load, wear resistance and tactile sensations depend on them.

The outer layer (braid) is also important, especially if the cable will have to be used in combination with stoppers or winches. Plus, you shouldn’t always chase fashionable dyneema; in some cases, the elastic end will do the job better than low-stretch fiber.

All of the above is also true for mooring lines. The quality of life on board, the integrity of the yacht and even the health of the crew largely depends on their material and weave.

Let us briefly list the main characteristics that are taken into account when classifying mooring ropes of various types.

Breaking Load

This indicator indicates the strength of the end and depends on the cross-section of the cable, its “design” - the type of twist or weave, the presence or absence of sheaths, as well as the material. According to this indicator, the cable should always be chosen with a reserve, but in the case of mooring lines, and even more so with scerves for fastening fenders, this rule is observed automatically in most cases (see the next paragraph).

By the way, in some cases, in the catalog tables, along with the breaking load, the so-called working strength is also given - a load that can be applied for a long time without the risk of damaging or breaking the cable. As a rule, it is about six times less than the breaking point.

Section or Diameter

Not only the breaking load depends on this indicator, but also the ease of use of the cable, which is especially important for mooring ends, which have to be selected with bare hands, and often under significant load. Even if you use a strong, but too thin cable, you will most likely cut your palms, so it is the diameter of the mooring line that is decisive when choosing the end for such purposes.

Catalogs of cable manufacturers often contain special tables, but the easiest way is to use the simple formula D = L+4, where D is the diameter of the mooring line, mm, L is the length of the boat, m. Thus, for a 6-meter boat, a cable with a diameter of 10 mm is suitable, although, to be honest, a couple of millimeters in one direction or another will not play a special role.

The smaller the boat, the more freedom you have when selecting a cable, as they say, “by touch” - simply assessing how it fits in your hand. At the same time, the thickness, determined according to the principle of ease of use, provides with a margin the necessary tensile load - taking into account not only the forces of wind and current influencing the boat standing at the pier, but also the motor thrust when maneuvering on moorings (of course, with reasonable use this method!)

Friction

Some cables are quite slippery, others not so much. For mooring lines, which are usually attached to cleats or bollards, this indicator is not so important, but when tying some knots, a slippery cable can create problems. This indicator is determined not only by the material and design of the cable, but also by its rigidity.

Rigidity

A rigid cable resists attempts to bend it more strongly, tending to straighten like a spring; the soft one can be bent in your fingers practically without forming a loop. In addition, the soft cable noticeably bends under the fingers, which is why the contact area in the assembly is larger and, accordingly, the friction force and reliability of the connection are higher.

Extensibility and Elasticity

Cables that practically do not stretch under load are primarily of interest to yachtsmen, who use them in running rigging to fine-tune the sailing rig. The mooring and towing ends, on the contrary, should have a little spring, because in some cases they have to play the role of shock absorbers, softening shocks; in the case of fender ends, this indicator is absolutely unimportant.

Tendency to Form Wickets

The wickets on the cable - multiple loops that form on their own, for example, when pulling the end out of the coil - a rather unpleasant thing. To get rid of them, the cable has to be untwisted in the opposite direction, which takes precious seconds. This disadvantage is primarily caused by rigid twisted cables, which we do not recommend for the purposes under consideration.

Relative Density

It is better if it is smaller - at least from the point of view that a coil of thick cable is already quite weighty. But the most important thing is the ability of the cable to stay on the surface of the water, which, for example, eliminates the risk of the gear getting wrapped around the propeller during maneuvers.

Design

Let’s not think about the countless varieties of twists and weaves that largely determine the characteristics of cables. Suffice it to say that the ends are twisted and braided, as well as with and without shells. Hollow cables are also often found - roughly speaking, one shell without a core. “Braids” are usually softer, and one or two braided shells not only improve this indicator, but also noticeably increase the friction force.

Flat “belts” stand somewhat apart - either monolithic or double in the form of a hollow stocking. As a rule, they are distinguished by excellent breaking characteristics, but for mooring needs, as well as for fastening fenders, they are still not very convenient. They can be recommended as anchor ends, especially since the considerable length required for such purposes can be easily, compactly and aesthetically hidden in a special reel, like a tape. By the way, some anchor electric winches are also designed for flat “belts”. They are also irreplaceable as fastening slings, especially when combined with mechanical tension locks.

Material Used

Now we mainly have to deal with synthetic cables made of polypropylene, polyester, polyamide, polyethene, of which the vast majority are on the modern market. Classic plant cables, however, have not completely disappeared from the scene either. They, of course, are somewhat inferior to synthetic cables in terms of strength (which is not so critical for a small boat), are heavier (since they absorb water more actively) and are susceptible to rotting. At the same time, they are softer, not so slippery and are not at all prone to “tanning” over time under load.

We will not discuss steel cables, since they are not used on small fleet vessels, especially on pleasure and racing yachts.

Now let’s take a closer look at some of the characteristics that will help you buy mooring ropes from the topRik marketplace that will effectively perform their main functions:

- securing the yacht to the pier while moored in the port;

- ensuring the stability of the yacht when moored on stilts;

- prevention of damage due to correctly selected fastening methods;

- prevention of drift due to the correctly selected size, diameter and elongation of the mooring rope;

- preventing drift into the open sea.

If you often change ports, marinas and lagoons, your yacht must have mooring ropes for all types of mooring. There are several types of mooring ropes depending on their location on the ship: bow, stern, side, diagonal (at an angle from the side to the pier).

By the way, the illustrations in this review demonstrate some of the most common methods of mooring yachts.

Types of Mooring Ropes

Mooring lines are classified according to several parameters, which we briefly listed above. And here we will dwell in more detail on those characteristics on which the rest in most cases depend. These include the material of manufacture of mooring lines and the method of their manufacture - design and type of weaving.

Materials

As already stated, this review does not discuss steel mooring lines as they are generally not used on small boats, much less fiberglass yachts.

But mooring lines made from natural threads also go down in the history of navigation. While some sailors are attracted to ropes made from plant materials because of their long-lasting softness, others are put off by the need for more careful care. Natural raw materials require washing and complete drying before storing if you want to prevent rotting and mold development. While synthetic mooring lines can be folded into a bay during the cleaning process, and immediately after washing and draining the water, they can be placed in a well-ventilated locker.

In addition, some mooring methods require more elasticity from mooring ropes, which moorings made from plant materials cannot provide.

Synthetic materials for cables can also be divided into two main groups:

- relatively inexpensive, but with qualities sufficient for use on cruise and small racing yachts;

- high-tech, withstand extremely high loads, but have a high price and are therefore used mainly on extreme racing yachts.

The first group includes fibers based on well-known chemical compounds, such as polyester (aka polyester), polypropylene and polyamide (nylon), as well as fibers based on modified polyethylene, such as Dyneema and Spectra.

Polyester is well known to yachtsmen in the form of fabric under the Dacron brand.

"Extreme" running rigging is made from aramid fibers such as Kevlar, liquid crystalline polymers such as Vectran, or fibers based on a new type of chemical compound known collectively as polybenzoxazoles (trade name Zylon). But since we are considering exclusively mooring ropes, we will not talk about aramid materials for the future.

Polypropylene (PP), or Polypropene Mooring Lines

Polypropylene fibers, like cables made from them, don’t have the best characteristics. Their main advantage is buoyancy, and therefore various kinds of throwing and winding ends are made from them. Polypropylene has low abrasion ability, does not resist UV rays well enough, does not stretch well and is not pleasant to the hands.

Polypropylene is two to three times cheaper than polyamide or polyester ropes and has extremely limited use on modern large yachts - for the most part, as the basis of some braided ropes. Sometimes lightweight polypropylene tackle is successfully used on small dinghies.

Polyamide (PA) or Nylon Mooring Lines

Polyamide (aka nylon) is one of the oldest synthetic materials. He has been known for almost 80 years. It has the greatest relative elongation, which naturally determines the main area of its use - anchor and mooring lines. This is where the elasticity of polyamide cables becomes their advantage - by stretching elastically, they absorb shocks well, reducing dynamic loads on the anchor device, bollards and cleats. Today this is practically the only area of application of polyamide ropes on a sailing yacht. Due to its high elongation, polyamide is not suitable for sheets and, especially, halyards.

Polyethylene (PE, HDPE), or Polyethene Mooring Lines

Polyethylene is hard, durable and completely unaffected by water. In ropes today it is found mainly in the form of HDPE - high-modulus polyethylene, high-density polyethylene. It is eight times stronger than steel ropes, despite being eight times lighter. It is also chemical resistant and buoyant . Minimal elasticity also makes polyethylene rigs a favorite for small boats and racing yachts. However, their main disadvantage is that they lose a lot of strength when knotted.

Modified polyethylenes such as "Dyneema" and "Spectra" are very widely used as running rigging. “Pure” fiber from these compounds has a very smooth and silky-slippery surface, so yacht ropes made from them are almost always braided with polyester or polyamide strands. Unfortunately, the need to use such braiding deprives polyethylene cables of another advantage - buoyancy. The resistance to abrasion and UV rays of polyethylene is quite good and the elongation is extremely low. Their main drawback is noticeable creep. For Dyneema fiber, the critical value is about 45–48% tensile strength. Being exposed to the specified load for two to three hours, a cable made of this material begins to deform plastically. It stretches, and subsequent removal of the load no longer leads to restoration of the original length of the cable. This feature of fibers such as Dyneema and Spectra leads to the fact that when a braided cable is stretched for a long time under load, its polyester braid can break. In addition, modified polyethylenes and cables made from them cost, on average, three to four times more than polyester fibers.

Polyester Mooring Ropes (PETP)

For several decades now, polyester fibers have remained one of the most popular for the manufacture of sails and all types of running rigging: halyards, sheets, mooring and anchor lines. The reasons for this: their good strength, high resistance to UV rays and abrasion, combined with low elongation and a relatively low price.

Today, as demands on specific rope properties increase, manufacturers are also using different combinations of synthetic materials to achieve the best and most desirable performance.

Designs and Types of Weaving

According to their design, all running rigging gear is divided into twisted (or twisted) and braided. Traditional twisted ropes, known to sailors for thousands of years, have almost gone out of use - they have been replaced by braided ropes, which in most cases have better characteristics.

The main feature of twisted cables is their high elasticity, the ability to elastically lengthen under load. In addition, it should be noted that such cables are highly resistant to abrasion, easy to weave , and “pleasant” to work with manually.

As a result, the main area of application of furled gear on sailing yachts these days is anchor and mooring lines, as well as the running ends of the still common composite halyards (the root part of such a halyard consists of a particularly flexible steel cable, to which a running gear made of twisted synthetic material is added). cable). Another area of application for twisted cables is the rigging of antique-style ships.

Braided cables have gained universal acceptance, although their production is more expensive than the production of twisted cables. Braided cables, in turn, can be divided into two groups: solid braided and composite, consisting of a central base (core) and an outer sheath (braid).

Fully braided cables do not have a sheath and are entirely woven from one type of fiber - usually eight individual strands. Naturally, such cables are either made from fibers that are resistant to UV rays, or are subject to special treatment that reduces their impact. Solid braided cables are cheaper to produce than composite ones.

The majority of braided cables are composite, having a core and a sheath. The core and braid in such ropes can be made from the same material, the most classic version is polyester-polyester construction, or from different ones - for example, when the core is made of dyneema, and the braid is made of softer and more comfortable polyester. The advantage of composite “braids” is the use of different types of fibers in the base and shell in order to combine their advantages and, if possible, avoid the disadvantages. In fact, such important characteristics as tensile strength, modulus of elasticity and elongation are determined by the material and design of the core, and the outer braid acts as protection against adverse influences, increasing the durability of the cable. In addition, thanks to the composite construction of the braided rope, it is possible to improve its characteristics, such as resistance to UV rays.

The basis of a braided cable is most often high-strength fiber. The core can be of different designs: from plane-parallel (not twisted) fibers, twisted and braided. The advantages of a base made of plane-parallel fibers are minimal elongation under load and high tensile strength, but the disadvantage is the difficulty of making splices and ogons from them.

Braided cables with a twisted base, i.e., made from high-strength fibers twisted into one strand, are even less susceptible to splicing, and in terms of strength and other mechanical characteristics they have practically no advantages over cables with a plane-parallel core. Most braided cables today have a braided core, usually consisting of 8-12 individual twisted strands (although designs of six strands are also available), which have high strength and low elongation, and a braided sheath. It can consist of a different number of twisted strands: from 8 to 32, while increasing the number of strands in the sheath helps to increase the smoothness of the surface of such a cable and reduce its abrasion in stoppers.

How to Choose a Mooring Rope

Most of the time, the fate of a yacht depends solely on the mooring lines, so these lines are incredibly important, no matter how little the average yachtsman thinks about them. The common choice for mooring lines is polyester and polyamide, also known by the trade name nylon. You can find ends made of lighter polypropylene on sale, but they wear out much faster, so they should only be used if the buoyancy of the mooring line is important. The elasticity of polyamide cables is 10% greater than that of polyester cables, which is undoubtedly a plus. But we must not forget about another quality of the material: with prolonged use, polyamide absorbs much more water than polyester, and because of this it shrinks. The ends become hard and uncomfortable to use.

Mooring lines made of polyamide (nylon) have high strength and elasticity, but their main advantage is considered to be their spring properties, capable of absorbing shock loads. Mooring ropes made of polyester (polyester) are characterized by high strength and wear resistance, retaining their characteristics even when wet. Products made from polypropylene are characterized by good strength and wear resistance, especially since the affordable cost allows us to consider polypropylene cord as a budget option. They are light (lower specific gravity than water, providing mooring lines made of polypropylene with positive buoyancy), non-hygroscopic, and resistant to chemically active environments.

Also keep in mind that lay cable , characterized by higher breaking loads, has lower shock-absorbing properties. And double-braided cables, in addition to the supporting braided core, also have a protective braided sheath.

In addition to the material and manufacturing method, when choosing a mooring rope, special attention should be paid to the diameter, the required length, and also know the maximum load and breaking force of the selected rope.

Diameter and Length of Cable

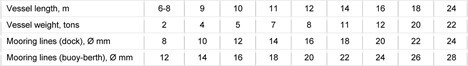

The size of mooring ropes depends on the length of the yacht. There are special tables that determine the ratio of the diameter of mooring cables, their length, the size and weight of the vessel, as well as the type of mooring device with which the cable is planned to be used.

There should be at least six ends on board, two of them about the length of the boat for attachment from the stern. At the bow there are usually enough mooring lines twice the width of the boat. Two additional ends should be kept in reserve for more complex maneuvers and parking. Here it is better not to skimp and focus on two boat lengths.

There are empirically obtained parameters for determining the length of the mooring end depending on its location, which yachtsmen adhere to:

- the length of the stern mooring line is 1.5-2 times the width of the vessel;

- side mooring length – 1-1.5 times the total length of the vessel;

- the length of the bow mooring line is 2-2.5 times the width of the yacht.

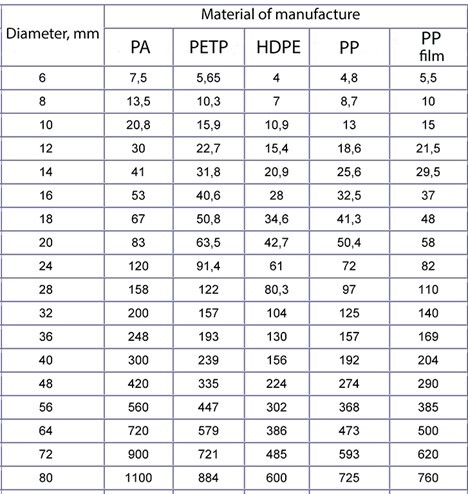

Load Characteristics

The maximum load that a rope of a certain diameter can withstand, or breaking force, is one of the most important characteristics of mooring ropes. We have prepared a table for you in which this characteristic is shown depending on the diameter of the rope and the material of its manufacture.

If you still have questions about choosing the right mooring ropes for your yacht, ask topRik experts right now through the site’s feedback form. These are experienced sailors who practice almost all year round and are well aware of the features of mass-produced motor and sailing vessels of any design. They will share professional secrets and help you choose the right rigging that exactly matches the features of your yacht.

The correct choice of mooring ropes is a guarantee of the safety of your yacht in any weather at any berth.