During the mooring and towing of a vessel, its hull invariably collides either with mooring devices or with the side of another vessel. In order to absorb these shocks, special devices called mooring fenders are used. They protect the board from deformation by distributing the impact force over the maximum possible area of the hull. In this article we will tell you about many options for fenders, from the simplest to the most complex, and how they function.

Towboats that never remove their fenders use old tires hanging along their sides, and huge ships use entire engineering solutions installed on piers that look like rubber shields. Inside these shields there can be either just a thick layer of rubber with a hole, or entire systems with liquids flowing through valves. The main task here is to create a large area of contact between the side of the vessel and the rubber surface. It is also necessary to make an impact damping system, since the impact of a multi-ton vessel is quite hefty.

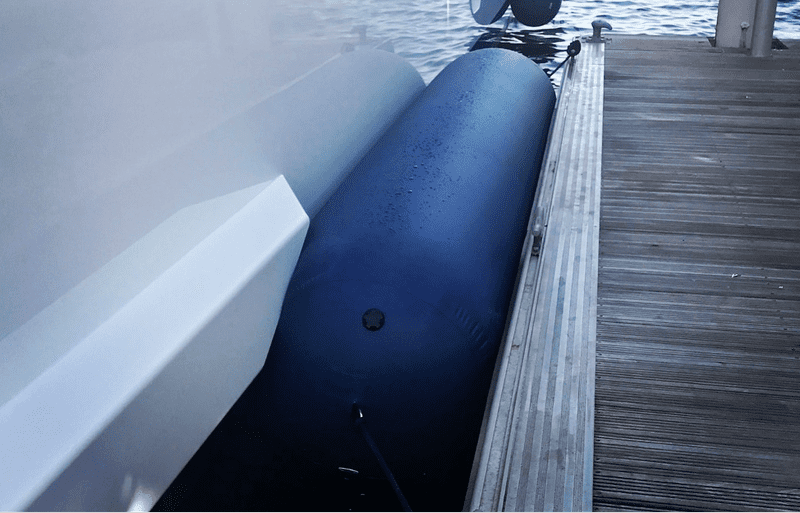

The owners of boats and catamarans need easy-to-use fenders for different berths, and besides, the fenders must be removed before each exit to the sea - otherwise the fender can fall overboard, wrap around someone's propeller and create a lot of problems. Offshore racing enthusiasts will attest that a fender floating in the water slows the yacht down.

Cylindrical Fenders

Cylindrical Fenders  Round Fender

Round Fender  Ladder & Steps Fenders

Ladder & Steps Fenders  Thru-hole Fenders

Thru-hole Fenders  Bow & Stern Fenders

Bow & Stern Fenders  Ring Fenders

Ring Fenders  Cushion and Flat Fenders

Cushion and Flat Fenders  Dock Fenders & Accessories

Dock Fenders & Accessories  Pile Fenders

Pile Fenders In general, yachtsmen will want something light and easy to put away. Moreover, it must dampen shocks well and fit the hull of the vessel, which designers try to make beautiful and angular, sometimes not really thinking about what kind of surface will face the concrete pier during anchorage.

Such fenders are classified based on their differences in the methods of energy conversion and distribution. They are:

- damping (gas, hydraulic);

- shock-absorbing (elastic, pneumatic fenders);

- combined (hydroelastic, hydropneumatic).

In addition, ship shock absorbers are divided into temporary and permanent. Temporary equipment is used on conventional ships. Permanent fenders are used on fishing and tugboats - they are placed on the bow and stern of the vessel.

Damping Fenders

The thick-walled shell of damping hydraulic fenders is made of rubber and has holes that dampen the compression energy due to the work of inelastic forces. Hydraulic devices are suspended in a vertical position, their buoyancy can be negative or positive. Water fills these fenders completely or halfway.

When the vessel's side collides with another floating craft, the shell is compressed, pressure increases in it, which leads to the displacement of part of the water through the existing holes. After contact with the shell is completed, water is restored in the fenders, the devices can take on new loads.

Shock-Absorbing Fenders

When mooring on the high seas, it is vital that the side of the vessel experiences a minimum of collisions. In order to solve this problem, shock-absorbing pneumatic fenders are used, which can be chambered and tubeless.

The rubber sheath of tubeless fenders can be reinforced with a cord made of metal or synthetic material. For chamber fenders (they are also often called two-layer) there are two shells - rubber-cord outer and sealing inner.

Combined Fenders

In the design of such fenders (including hydropneumatic ones) there are two shells, of which the inner one is filled with air or gas.

The space between the shells is filled with water, which is displaced at the moment of compression. These shock absorbers are less bulky and are suitable for both large boats and small boats.

The Principles of Pier Fenders Operation

Berth fenders can have different ways of completing their job. And, by the way, when it comes to pier protection, words “fender” and “bumper” are usually used interchangeably.

Some of them are designed to be used at various ports and berths and protect the berthing structures of the vessel’s hull from damage during mooring and possible rocking in the port water area. Pier dampers are composite technical products, the main purpose of which is to protect the berthing facilities and the ship's hull from damage that may occur during mooring or while anchored.

This is a necessary element of any pier, regardless of the types and sizes of ships that it invites in. To perform the main shock-absorbing function, the design of these devices and the materials used for fenders must have both high strength and sufficient flexibility. Based on our own experience, equipped docks save you from the risks of serious repair costs and increased insurance costs.

The main characteristics of fenders, which determine their operational capabilities, are energy intensity and response to compression.

Such mooring devices can be of two types: in the form of rigid structures and the shock absorbing type. Rigid fenders only protect those elements of the berth that are in direct contact with the vessel, and bumpers such as shock absorbers, in addition to direct protection of structures, absorb part of the energy of the mooring vessel.

The main types of bumpers are shown here in one picture. Round ones dampen energy by compressing the cylinder, while conical ones “swell up”.

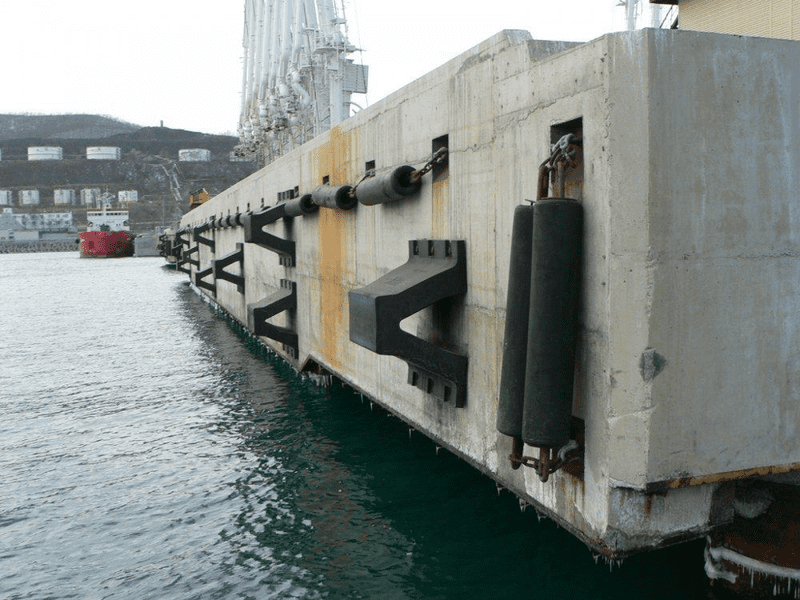

Cylindrical Pier Fenders

It is the very first, time-tested constructive modification. Represents an elastic gasket of a cylindrical type, suspended from the berth with the help of powerful chains. Ideal for fixed berths serving any type of ships: cargo, passenger, fishing, tugboats, pontoons. The operation of hydraulic structures of this type is extremely simple in installation and maintenance. At the same time, cylindrical models are durable and wear-resistant, which ensures reliability and durability.

Arch Pier Fenders

Mooring device in the form of a rigid one-piece cast bumper. A steel plate can be additionally embedded in the front part. This makes it possible to install a frame made of steel or a plate made of ultra-high molecular weight polyethylene at the front. Also, the device can be placed in the area behind the piles. The arched fender is available in several types, they differ in cross-section and width of the front surface, hence the differences in load. They perform well when it comes to tensile, compressive, shear, bending and twisting deformations.