topRik's experts explain how you can continuously monitor the health of your batteries, power consumption, PV, generator and grid energy collection in real time.

We also talk about battery monitoring systems for yachts, which you can buy at our marketplace to easily manage shore input power, automatically start or stop generators and select parameters for optimal system performance. Did you know that you can remotely troubleshoot power problems on your yacht from anywhere in the world? More on that later.

Effective monitoring of the condition of batteries on a yacht is a guarantee of safety and comfort for the crew, as well as significant savings in money that you could spend on frequent battery replacements. At any time, you can prevent the danger to the crew and the vessel itself that can be caused by undercharging or overcharging batteries.

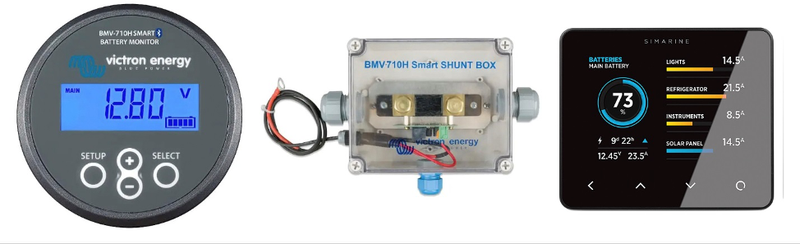

The topRik marketplace offers a wide range of monitors, battery monitoring systems, as well as digital switchboards for controlling all parameters of a yacht’s electrical system from the world’s best manufacturers of marine electrical equipment – Victron Energy, Mastervolt, Simarine, Blue Sea Systems, Ultimatron France, Yacht Devices etc.

Key Parameters to Monitor

During operation, due to many factors, batteries become unusable, and single one-time checks do not always detect their malfunction in time. And identifying the causes of the malfunction only confirms the lost time for timely diagnosis.

Typically, lead-acid batteries are supplied charged and ready to use. At the same time, the manufacturers' operating manuals emphasize that the batteries must be fully charged before commissioning. This is due to the fact that often from the moment the finished product leaves the assembly line of the manufacturing plant until it reaches the customer, a certain time passes, during which the so-called natural self-discharge occurs (within 3% per month).

But this does not mean that there is no need to monitor the batteries during operation, even if you pre-charge them and place them on the yacht and then connect them to the load.

An important indicator is the internal resistance of the batteries, which affects the amount of voltage reduction when current flows. Regular measurements of internal resistance make it possible to predict the depletion of battery life and plan its replacement in advance.

Battery elements whose resistance differs from the average calculated for all elements by more than 10% are subject to a training charge and if it does not produce the desired effect, they are considered faulty and need to be replaced. But here it is necessary to take into account that the internal resistance of batteries is a conditional value.

For example, a lead-acid battery is a nonlinear device, the internal resistance of which does not remain constant, but changes depending on temperature, load, state of charge, electrolyte concentration and other parameters. Therefore, to carry out accurate calculations of the battery, it is still advisable to use discharge curves, and not the value of internal resistance.

If the facility uses low-maintenance batteries with liquid electrolyte, then one of the indicators is the density of the electrolyte, which can be measured with a conventional hydrometer. A decrease in electrolyte density by an average of 0.02 g/cm3 or more from its nominal value for these types of batteries indicates the occurrence of irreversible consequences, such as falling off of the active mass of the grids or deep sulfation of the electrodes.

Batteries must not be discharged below a certain level. The end-of-discharge voltage is the minimum operating voltage of the battery. If battery discharge continues after the end-of-discharge voltage has been reached, the battery may be damaged or discharged to the point that it can no longer be used.

The main indicator of battery performance is the residual capacity indicator. The main task when checking is to find out whether the battery has sufficient capacity and whether it can provide the characteristics declared by the manufacturer for the required time.

Battery capacity characterizes the battery's ability to store energy and determines its operating time without recharging. Rechargeable batteries are considered operational until they deliver at least 80% of the capacity declared by the manufacturer. To identify this performance limit, during operation throughout the entire service life it is necessary to periodically check the batteries for compliance with their declared characteristics. The most important indicator here is the actual capacity at a given time.

The released capacity is the charge that the battery releases before its voltage becomes equal to the end-of-discharge voltage. Available capacity is the available capacity of a fully charged battery. For a new battery, the available capacity is equal to or slightly different from the nominal capacity. During operation, the available capacity decreases.

State of charge (SoC) is the ratio of released capacity to available capacity. Characterizes the current battery charge. Measured as a percentage.

Serviceability (SoH) is the ratio of available capacity to nominal capacity.

The voltage of a fully charged battery is higher than that of a discharged battery. The simplest control method is based on this fact - measure the current battery voltage and compare it with the voltage of a fully charged battery. However, such an assessment turns out to be not very correct. With it, we can only say with certainty that the battery is 100% charged, or that it is completely discharged. The lack of maximum accuracy is due to the fact that at a given state of charge and different load levels, the instantaneous battery voltage is not constant, but fluctuates up and down.

Voltage surges depend on the internal resistance of the battery. If the discharge current is very small, then the internal losses are not large, and the battery charge is almost equal to the maximum possible. At higher loads, losses increase and the charge supplied by the battery until the minimum operating voltage is reached is less.

If a dedicated battery is used to start the engine, then it is not necessary to measure the current consumed and supplied by it. On the starting battery, only the voltage is monitored. But on the service battery, the input and output current, voltage and charge level are measured.

If there is no pure starting battery on the boat, and both batteries are alternately used to start the engine and to power on-board equipment, install two shunts or move the shunt so that current from both batteries flows through it.

Types of Battery Monitoring Systems and Devices, Pros and Cons

topRik marketplace has selected equipment for monitoring batteries, taking into account the fact that all our visitors have different boats and different needs for monitoring the condition of batteries. As already mentioned, we have selected for you the best that the marine equipment market has in this regard.

You can buy here both basic battery monitoring devices (voltmeters, ammeters, charge status indicators) and more advanced multifunctional battery controllers, as well as intelligent energy management systems with the ability to switch using a digital control panel, as well as data transfer even to your multifunctional chartplotter, including via NMEA2000, CAN or Ethernet highways.

Basic Monitoring Systems

Often, many users use conventional multimeters (or voltmeters) to measure voltage. Some people use more complex and expensive devices with the ability to measure both open-circuit voltage and internal resistance. For starter batteries, a so-called “load fork” with different load currents is used.

However, only a few basic parameters are determined directly by measuring instruments - voltage, internal resistance, electrolyte density (for flooded batteries), current strength. All other parameters and characteristics are not measured directly, but are derived using a method developed by the manufacturer.

It is necessary to take into account that many dependencies characterizing the operation of batteries, as mentioned above, are nonlinear. Factors such as the type of battery, load characteristics, operating temperature, manufacturer's recommendations and others may have an effect.

Instead of determining the condition of the battery by voltage, you can measure current. The amp-hour meter monitors the current received and released by the battery, sums it up over the period of use and adds the calculated value to the initial charge of the battery. Since the initial state of the battery and the charge-discharge current can be measured quite accurately, the ampere-hour meter determines the current state of the battery more reliably than a voltmeter. However, it also has several disadvantages.

As with any device, there are losses in the battery, so the charge it gives out is always less than the charge it receives. Losses are not constant, but depend on temperature, charge-discharge current and battery age. The efficiency of the same battery varies in different conditions.

However, the coulometer does not take into account losses, and over time its readings become more and more different from the actual state of the battery. To avoid discrepancies, coulometers must be recalibrated regularly.

If the battery is disconnected from the load and left without recharging, then no current will flow through the current-measuring sensor of the coulometer. But chemical reactions in the battery will still occur, and over time its energy will decrease. After a week, the cell voltage and battery condition will change, but counting the coulombs will not tell you anything about this. The coulometer does not take into account battery self-discharge.

During use, the available battery capacity decreases. The coulometer cannot determine the current capacitance value , and it regularly has to indicate the upper and lower reference points. This is done by completely discharging and charging the battery. In real conditions, this is not always possible, and over time, the coulometer readings become less and less accurate.

Today, the market offers many devices for express analysis of the condition of batteries at a given time, based on the operating principle of a “load fork”. Unfortunately, this equipment has a large measurement error, which the manufacturers themselves do not hide. It is also necessary to take into account that the measurement results are formed due to internal calculations based on the same data on voltage, internal resistance, conductivity, minimum current load, etc., which again leads to an error in the results.

Therefore, today, as many years ago, the most effective, proven, objective and accurate way to check the condition of batteries is a control 20-, 10-, 5-, 3- or 1-hour discharge. It is necessary to take into account that the longer the time period of the discharge, the more objective the results will be.

However, despite the fact that this method of assessing the condition of batteries is the most direct and reliable, it requires special equipment, a lot of time and labor, and is not always acceptable when it is not possible to disconnect the battery from the main load and replace it with backup batteries, for example, on a yacht on the open sea.

It should be recognized that all of the above measuring instruments as monitoring the condition of batteries are not even yesterday, but the day before yesterday. If only because they are not able to show correct data in real time.

Even the most conservative sailors have already admitted that a battery monitor is the simplest device that can monitor the condition of the entire electrical system on a boat or yacht. The current is measured at the generator output and at the input and output of the service battery. At the starter battery, only the voltage is monitored.

A modern battery monitor is not just an amp-hour meter, but an intelligent battery monitoring device. Before starting work, the nominal capacity of the battery is entered into the monitor, over several cycles the device “learns” and then works without outside intervention. The monitor monitors the current, voltage and temperature of the battery and compares the received data with its own battery model. Based on actual data, the model parameters are adjusted, and it constantly corresponds to the real state of a working battery.

Battery monitors can monitor one or more batteries. The simplest device measures the voltage, current and charge of a single battery. More advanced models are designed for two or three battery groups. For the main battery they measure voltage, current and charge, and for additional batteries only current and voltage or only voltage.

Advanced Monitoring Systems

Models of battery monitors that have a modular principle allow you to add up to 20 independent current sensors or intelligent shunts to the circuit, and use them to control up to 6 batteries. Such monitors have a built-in Wi-Fi module and transmit information about the battery status to the owner’s smartphone or tablet.

Additionally, a properly installed battery monitor is an indispensable tool for troubleshooting the electrical system of a yacht or camper. Yes, such monitoring systems can also be installed in mobile homes, they work great, as our team was convinced of by the example of PICO monitors, and later by a more advanced battery monitoring system from the same company, Simarine, which we installed in our caravan, and we still use this system today.

Later versions of PICO are no longer just a battery monitor, but a real system for monitoring the condition of rechargeable batteries, since thanks to the presence of modules and shunts, it is possible to measure and control the temperature regime, as well as the amount of energy incoming and wasted from different sources, and for each powerful device At the same time, the system performs the task of battery switches, which can be controlled not only using the display, but also remotely.

An example of multifunctional battery controllers is the Ekrano GX, the latest addition to Victron's Energy GX series of products. With extensive connectivity options and interfaces, as well as a 7" touch display, it allows you to operate your system smoothly from anywhere. You get instant status monitoring:

- batteries;

- energy consumption;

- photovoltaic systems;

- generator and collection of electricity from the network;

- tank level;

- temperature conditions.

Via intelligent energy management systems set and Nereide 2 set from Simarine, with the Ekrano GX you can easily manage shore power input, start and stop generators, and fine-tune parameters for optimal system performance.

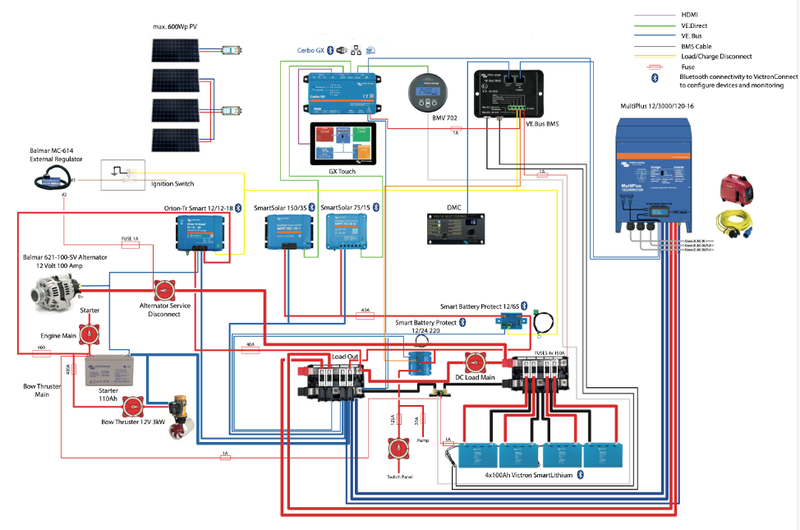

Using digital intelligent systems with switchboard control panel from Simarine or Victron Energy you can troubleshoot problems with your yacht's power supply remotely. At the beginning of the article, we provided a working diagram for organizing power supply and monitoring the yacht’s electrical system using Ekrano GX.

Of particular note is that advanced battery monitoring systems support NMEA2000 or CAN protocols, and can also transmit information over Ethernet highways in real time.

In Simarine systems this function is facilitated by a specially designed shunt module SN 01 NMEA 2000 Gateway.

At the same time, we do not particularly dwell on the additional capabilities besides battery monitoring that multifunctional controllers or intelligent energy management systems provide the yacht owner. After all, we have repeatedly talked about the advantages of using these systems with options for various modules.

As an example, we provide a table with options for organizing control of the electrical system on boats of different sizes using an intelligent energy management system using the Nereide 2 set switching model from Simarine.

One of the most important benefits of smart battery monitoring systems is the ability to not only observe measurements and changes remotely. You can also remotely control the entire process of energy supply and distribution.

Each manufacturer of such a system develops an application that is posted on the Internet for free download. After downloading the next version, you install the application on your device - a smartphone or similar, and now you see on the screen of your device the control panel of the monitoring system installed on the yacht.

As we said, you can not only observe the process, but also correct it, for example, disconnect any household appliance from power, switch the power source - say, from a generator - to a solar panel, etc. That is, you don’t have to worry about the condition of the yacht left at the pier when you go out into the city. You can check the operation of your electrical system at any time without leaving your local cafe.

We know that some sailors are afraid that with a change in the monitoring system, they will have to overhaul existing equipment, which still performs its functions, although it requires additional effort and time spent on calculations, which exclude intelligent systems and even ordinary battery monitors.

The good news is, as always when dealing with the topRik team, all modern battery monitoring systems are compatible with almost all modern navigation equipment. For example, Victron Energy and Raymarine even have an agreement on this matter.

When developing numerous modules and shunts of Simarine systems, the most common connectors and other compatibility issues are also taken into account. That is, if you have a modern yacht with modern electronics and electrical navigation equipment (autopilot, echo sounder, ASI, thruster, winches), you will be able to integrate an intelligent control system at no additional cost.

But if you have questions about equipping your yacht with modern or traditional systems and monitoring devices, contact topRik experts for a free consultation.