In this guide we’ll try to give some advice on how to determine that it’s time to replace your mooring rope with a new one. Or could it can be repaired somehow? Maybe in this condition it’s good for another cruise? To avoid such doubts, follow the recommendations, born from long maritime practical experience of topRik experts.

The strength of a mooring rope depends on a large number of factors - the quality of the source material, the type of rope itself, manufacturing process, operating conditions and the correct selection of the type of moorings for these conditions.

Major Signs of Wear and Damage

While signs of mechanical damage to the mooring ends can be determined visually, not all signs of changes in the cable structure are immediately evident. Therefore, regular inspection of moorings must be carried out very carefully, sometimes with the use of special devices.

Let's take a closer look at the main signs of wear and damage that you should identify during a mooring inspection. Such an inspection is recommended to be done after each mooring, especially if the yacht and cables have experienced adverse weather conditions while moored. It may well be that only your boat survived them safely, and the mooring lines served their time.

Visible Damage

Violation of the integrity of the mooring cable is what we see with the naked eye: fraying, cuts, tears and/or frayed fibers. The cause of such damage may be operating features or improper use of moorings.

- Friction. During operation, the surface (braid) of the rope wears out. It is necessary to avoid contact of the rope with abrasive elements in order to prolong its service life. It is necessary to avoid getting sand, dust and other solid particles between the fibers of the rope. They will render the rope unusable very quickly, “cutting” the fibers. Intensive pulling of the rope, especially under heavy loads, causes local overheating, even melting.

- Bend radius. When working with rope, there are almost always places where the rope bends (rollers, pulleys, etc.) In this place, the load on the fibers is not distributed evenly, i.e. Some of the rope fibers do not work, and some are heavily loaded.

- Knots. Reduces the strength of ropes by 30 to 60%. Knots, as a rule, violate the structure of the rope. Constrictions and bends of fibers occur, as a result of which the load is not distributed evenly and the rope fibers do not work equally.

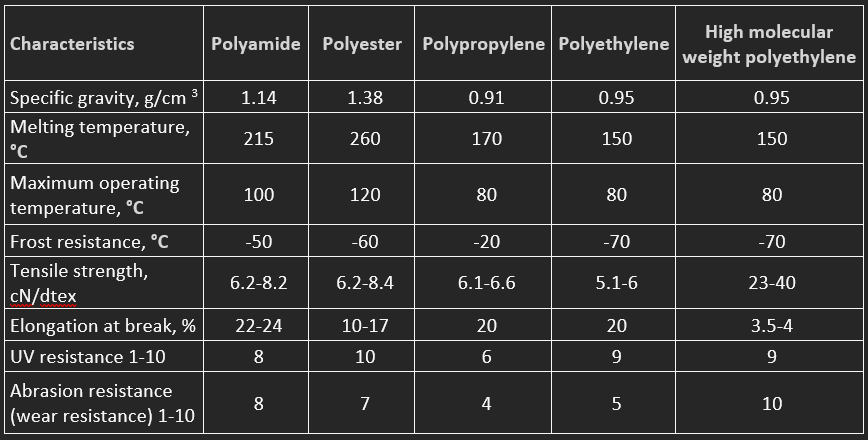

Therefore, if you want mooring lines with high wear resistance, choose ropes made of high molecular weight polyethylene or polyamide.

Changes in Cable Structure

Not all synthetic materials are able to maintain their original properties for the same period. For example, ropes made of polyamide, polyethylene and polypropylene maintain elasticity longer. Polyester fibers have less elasticity and lose it faster. The same applies to cables made of high molecular weight polyethylene. Loss of flexibility can lead to difficulties when mooring, and loss of elasticity can lead to the rupture of mooring lines during mooring in strong waves.

If you notice that an unnatural twisting of fibers has appeared on a section of the cable that cannot be straightened or knots that cannot be untied, this is also evidence that changes have occurred in the structure of the lines. Such ends should be replaced, since the cause of such twists may be a violation of the integrity of the individual core fibers.

Impact of External Factors

Environmental influences also contribute to the aging of ropes and a decrease in their strength:

- sea water with a high salt content, which, in addition to the negative impact on the synthetic part of the moorings, can cause corrosion of the metal parts of the mooring rope;

- pollution by marine microflora and microfauna, bottom silt and sand;

- ultraviolet radiation, prolonged exposure to which leads to discoloration and brittleness of synthetic fibers, especially for polypropylene cables;

- cycles of temperature changes;

- high humidity, which leads to rot and mold;

- possible contact with substances aggressive to synthetic fibers.

Under the influence of these factors, synthetic threads become thinner and become brittle. Therefore, you should choose mooring lines depending on the conditions in the water area you visit most often. For example, if your choice is the tropics, then choose mooring lines, in the production of which light stabilizers are used.

Specific Problems with Different Materials

As you understand from the above, you should be well aware of the properties of the fibers from which marine ropes are made, in particular mooring ropes. What basic properties do you require? We will choose tensile strength, elasticity and buoyancy as mandatory. The desired ones are abrasion resistance, lightness (the same buoyancy), ultraviolet resistance and minimal water absorption.

By now you should understand that all your wishes can not be satisfied by any one synthetic material that is used to make mooring ropes. Therefore, it is better to make a choice taking into account specific problems of each main polymer fiber.

Nylon (Polyamide) Ropes

Main properties of nylon cables:

- specific gravity – 1.14 g/cm³;

- high stretchability;

- high strength, wear resistance;

- high resistance to ultraviolet radiation;

- good resistance to alkalis and organic solvents;

- moisture absorption – 1-7% by weight;

- operating temperature -50 to 100°C (melting point 215°C).

That is, despite many positive aspects, including low price, there are also disadvantages. At this specific density, the thrown end will sink if it hits the water. And this should not be allowed with nylon ends - when wet, their strength significantly decreases, which threatens ruptures. And due to shrinkage when wet, the polyamide cable loses its elasticity.

Polypropylene Ropes

Polypropylene is perhaps the most common synthetic material used for ropes today. And this is not surprising if you know the basic properties of lines made of polypropylene:

- floating on water, zero moisture absorption;

- they do not lose strength and elasticity when wet, do not rot;

- high strength and good wear resistance;

- UV stabilization;

- suitable for tying knots;

- harmless to health;

- specific gravity 0.91 g/cm³;

- good resistance to acids, alkalis and solvents;

- operating temperature in an environment from -20 to 80 ° C (softening temperature 140° C, melting temperature 170° C);

- large selection of colors.

You should know that there are multi-strand continuous polypropylene fiber cables, as well as polypropylene film cables with thin film flat fibers. The latter material has higher breaking strength, but it wears out faster. Therefore, when using ropes made of such material, you should carefully examine the deck equipment with which they come into contact: cleats, bollards, etc. Sharp edges should be covered with leather, canvas, plastic hoses to protect the mooring lines from rapid abrasion.

Polyester Ropes

Let's discuss another popular material from which marine lines are made – polyester or lavsan.

Its demand is explained by the fact that sailors appreciated the basic properties of such ropes and cables, including:

- very high strength, excellent wear resistance;

- high resistance to ultraviolet radiation;

- operating temperatures from -60 to +120°C

- specific gravity of 1.38 g/cm³;

- they do not change properties when wet.

And yet its low elongation (insufficient elasticity) accelerates the process of wear from friction and, even more so, from the constant long-term loads that mooring ropes experience during moorings. For those who do not tend to spend a lot of time in ports, this is an excellent choice.

But knowing the characteristics of materials used is not enough to make the right choice. One should also take into account the manufacturing method, which can significantly improve the initial characteristics of synthetic raw materials - the so-called technological factors.

Strength depends on the type of rope (structure/construction). The main point is to design the rope in such a way as to fully utilize the strength of each thread – it usually shines when under longitudinal loads. Let's look at the most common types of ropes.

Three-strand twisted ropes. The heels (groups of twisted threads that make up the strands of the rope) are located almost parallel to the rope. The coefficient of utilization of the strength of the original threads is quite high. However, the cut of the rope clearly shows that there remain significant “voids” that could be filled with threads, and therefore increase the strength of the rope. But the design of the rope does not allow this. Therefore, this type of twisted rope has an average “useful” strength.

Pros: easy to manufacture (cheap); convenient for splicing.

Among the disadvantages, one can note the tendency to “unwind” (it is necessary to fix the ends of the rope) and the formation of loops (knots) when the rope is without load, in a free state.

Braided ropes (single-braid). One of the most common types of braided ropes without a core. As a rule, they are produced in 8-, 12-, 16-strand variations.

As the number of strands increases, the “useful” strength of ropes of this category decreases (the rope sections will have significant voids in the center). In addition, with increasing spunness, the angle of inclination of the threads increases - i.e. under load, not only longitudinal but also transverse stresses arise. In this subgroup, 8- and 12-strand L-type ropes are the leaders - they have good “useful” strength.

Double weave ropes (double braid). They have the structure of a braided core and braid. There are no voids in the cut, very high “useful” strength.

Ropes with parallel cores (single-braid). Consist of twisted cores and braid. Similar to double-weave ropes, there are no voids in the cut, very high “useful” strength.

Rope Strength Testing

Testing of marine ropes is carried out by the manufacturer during the production process in accordance with ISO, DIN or EN standards for each type of material, for example the following:

- ISO 9554:2005. Fiber ropes – general specifications;

- ISO 1346:2004. Fiber ropes. Polypropylene split film, monofilament and multifilament (PP2) and polypropylene high-tenacity multifilament (PP3). 3-, 4-, and 8-strand ropes;

- ISO 10572:2009. Mixed polyolefin fiber ropes;

- ISO 10554:2009. Polyamide fiber ropes. Double braid construction.

They are updated regularly but are based on ISO 2307:2005: fiber ropes – determination of certain physical and mechanical properties. These are the standards that marine rope manufacturers must adhere to when testing the physical and mechanical properties of their products. Therefore, when purchasing mooring ropes, always check that your choice complies with ISO, DIN or EN standards.

Manual Testing

But over time, any cable used on a yacht begins to lose its properties. Is it possible to check at least the basic characteristics of seemingly deteriorating mooring lines? For that we have the manual testing option.

First of all, this is a visual inspection. If abrasions or tears in the strands are detected, you should select the most worn and damaged section 0.3-0.5 m long. The rope in this section is slightly untwisted, then all the strands are untwisted one by one. This is done in order to determine the number of broken and damaged filament threads (monofilaments or fibrillated film threads).

The degree of rope wear is the ratio of the number of damaged threads to the total number in the new rope and is expressed as a percentage. It is recommended to replace the mooring or towing rope if in its working part the number of breaks and thread damage is 15% or more of the total number of rope threads. The length of the working part is taken to be 8 diameters for twisted three-strand cables and 10 diameters for eight-strand braided ones.

Loss of breaking load of a synthetic rope due to prolonged exposure to sunlight is the ratio of the difference between the breaking loads of the nominal and after exposure to sunlight to the rated breaking load of the new rope and is expressed as a percentage.

The norms for the loss of breaking load of a rope, depending on the duration of their continuous exposure in the open air, are established experimentally for each standard size of rope.

Due to the absence of such standards, it should be assumed that the loss of breaking load of a rope is after its continuous exposure to the open air for:

- 4 months: polyester – 2-3%; polyamide – 4-6%; polypropylene – 6.8-8%;

- 8 months: polyester – 3-5%; polyamide – 6-8%; polypropylene – 8-10%;

- 12 months: polyester – 5-8%; polyamide – 8-10%; polypropylene – 12-15%.

The loss of breaking load of a synthetic rope from exposure to sunlight decreases with increasing its size (circumference, diameter). For ropes with a circumference from 90 to 150 mm, the loss of breaking load from exposure to sunlight is 1.3 times and for ropes with a circumference over 150 mm - 1.5 times less.

If after checking for cracks and weak points, tears, discoloration, spots of rot, mold or rust, the condition of the mooring line is assessed as good, all that remains is to check it for tension and elasticity.

The elongation of moorings depends on the material and type of rope. By extensibility in a decreasing direction, you can build the following list:

- polyamide;

- polypropylene;

- polyethylene;

- polyester;

- high molecular weight polyethylene;

- aramid.

The high elongation of the rope allows it to absorb sudden loads (jerks) - this property is in demand when towing, mooring, etc.

Low elongation is necessary when using ropes for winches, lifting mechanisms and for steering (traction) systems in some vehicles, usually water vehicles.

You will feel the increase in rope rigidity to the touch. And the presence of residual elongation can be determined if the rope is marked with indelible marks or thin rubber rings before use.

To absorb loads on the cable, mooring shock absorbers can be used.

Using Specialized Tools

Specialized instruments such as dynamometers can be used to measure the load on a ship's ropes and their tension. They can be mechanical or electronic.

A portable measuring device is installed permanently either directly on the winch frame or with the help of anchors on any flat surface. To measure the force, the cable is inserted between the guide rollers of the device. The digital unit of the device displays the current value of the cable tension force.

Electronic devices consist of a strain gauge connected by a communication cable to an electronic measuring indicator. The indicator scale is named in kN (N) with the ability to switch to kilograms or tons.

FAQ

How does ultraviolet radiation affect mooring lines?

Ultraviolet radiation can cause discoloration and deterioration of the structure of the material, making it brittle and less durable. Therefore, polypropylene ropes should not be allowed to remain in direct sunlight for a long time, since of all the materials from which mooring lines are made, polypropylene is most susceptible to the destructive effects of UV.

Which mooring rope materials are most resistant to wear?

In the properties section of the materials from which mooring lines are made, there is a table that indicates, among other things, the level of resistance of synthetic ropes to UV exposure. Polyester ropes are generally more resistant to wear and UV damage than nylon and polypropylene ropes.

How can you tell if a cable has lost its elasticity?

Loss of elasticity manifests itself in the rigidity of the line and its inability to return to its original shape after stretching. A cable that has lost its elasticity should be replaced at the first opportunity, since with the same constant voltage the likelihood of it breaking increases.

Can improper storage affect the condition of the line?

Yes, improper storage, for example in conditions of high humidity or direct sunlight, can accelerate the wear of the cable and reduce its strength. Marine ropes must be stored clean and dry indoors at a temperature not exceeding 30° C and a relative humidity not exceeding 70%.

What to do if the cable begins to rot or mold?

A cable showing signs of rot or mold should be replaced immediately, as such damage reduces its strength and reliability. During operation, the process of rotting and molding will continue, no matter how well you wash the cable. Mold spores and fungi cannot be removed with detergents. Under the influence of sea water and sunlight, they will spread more actively, and the wear of the lines will increase, which can lead to ruptures at the most crucial moment of mooring.

Is it possible to repair a damaged mooring rope?

In some cases, temporary repairs may be possible. You can remove the damaged area and connect the remaining fragments. But they should be connected not using a knot, but by splicing. When you tie a knot, the strength of your rope is reduced by 20% compared to splicing, which maintains 100% rope strength.

But to ensure maximum safety, it is recommended to replace the damaged cable with a new one as soon as possible.